Volvo's New Wheel Loaders Run Cleaner, Stingier

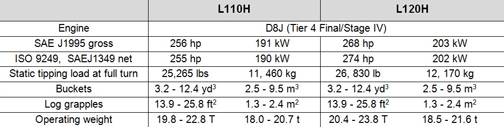

Volvo's new L110H and L120H wheel loaders tout fewer emissions and stingier fuel use with the company's new 8-liter Tier 4 Final/Stage IV-certified engine. Matched with its OptiShift transmission, the company says, the loaders can improve fuel efficiency up to 18 %.

These 18-22 ton class loaders also feature intelligent hydraulics, which only supply power on demand. The load-sensing hydraulics ensure fast response for control over the load, as well as shorter cycle times. Their Reverse-By-Braking (RBB) function automatically reduces the engine rpm and applies the service brakes when the operator changes the machine's direction, conserving fuel and reducing drivetrain stress.

These 18-22 ton class loaders also feature intelligent hydraulics, which only supply power on demand. The load-sensing hydraulics ensure fast response for control over the load, as well as shorter cycle times. Their Reverse-By-Braking (RBB) function automatically reduces the engine rpm and applies the service brakes when the operator changes the machine's direction, conserving fuel and reducing drivetrain stress.

Ready for a wide range of applicaations, from material handling and rehandling and road construction to utility work, the wheel loaders can be fitted with a choice of attachments, including buckets, material handling arms, forks, sweepers and snow blades to help optimize machine use and ROI. The attachments are designed as an integral part of the wheel loader, with functions and properties ideally matched to minimize energy losses and increase productivity. Meanwhile, the Torque Parallel (TP) linkage delivers high breakout torque and parallel movement throughout the entire lifting range and the optional Boom Suspension System (BSS) reduces bucket spillage, boosting productivity by as much as 20 percent on rough ground.