Two New Soil Compactors From Volvo

Volvo's SD75B and SD115B Tier 4 Final soil compactors are designed to handle applications ranging from highway projects to general site preparation. They feature advanced technology to enhance productivity and are designed for durability and serviceability.

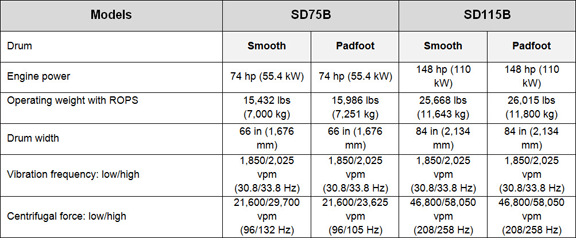

They new compactors have an advanced drum control that easily allows the operator to adjust the frequency and amplitude, compensating for changing soil types and conditions. Two frequency settings come as standard, but five can be included as an option. High or low amplitude can be selected to adjust the drum’s dynamic force based on the job and material depth. Meanwhile, the optimized centrifugal force and auto-vibration feature enhance performance, ease of operation and productivity. (Specs are shown below.)

They new compactors have an advanced drum control that easily allows the operator to adjust the frequency and amplitude, compensating for changing soil types and conditions. Two frequency settings come as standard, but five can be included as an option. High or low amplitude can be selected to adjust the drum’s dynamic force based on the job and material depth. Meanwhile, the optimized centrifugal force and auto-vibration feature enhance performance, ease of operation and productivity. (Specs are shown below.)

The traction system provides excellent climbing and stability in difficult applications, such as steep inclines or slippery surfaces, preventing wheel or drum spin for excellent gradeability.

The SD75B and SD115B can be set up in three different configurations and are available with a smooth or padfoot drum. The compactor can also be quickly and easily converted from a smooth drum by clamping on a padfoot shell — further improving versatility.

“These new models offer the perfect mid-range size and exceptional versatility to accomplish any compaction job,” said Mark Eckert, compaction product manager at Volvo Construction Equipment. “The SD75B and SD115B adapt to changes in conditions, ensuring the contractor can use it for any job that arises — no matter the application or the terrain.”

The Tier 4 Final Volvo engine delivers high torque at low rpm for reduced emissions and fuel consumption without compromising on power. ECO mode now comes as standard on the SD75B and SD115B models and can achieve up to a 40 percent reduction in fuel consumption. The intelligent design provides quicker ramp-up speeds at lower pressure, further increasing fuel efficiency.

The passive regeneration automatically cleans the filters during normal operation without any input from the operator or negative impact on performance. The hydraulically driven fan with variable speed draws power only when needed, which reduces noise, improves operator comfort and results in a lower total cost of ownership.

The cab provides excellent visibility, grouped ergonomic controls and a comfortable environment, is ROPS/FOPS certified, and has floor-to-ceiling glass with clear sightlines to the forward drum. The adjustable seat enhances visibility and comfort. The new color operator display shows operational information and key diagnostics, and is visible even in bright sunlight.

Both models are backed by the Volvo Lifetime Frame and Structure Warranty, which covers the frames and articulation joints of the compactors. The heavy-duty drum, center joint and front frame components are engineered and manufactured for longevity and performance. All components and electronics have been moved into the cab and mounted on the rear wall to protect them from harsh environmental factors.

A tilting cab is standard on the B-Series models to provide easy service access to all hydraulic components. The engine hood lifts electrically for extensive ground level access to the engine compartment. Maintenance and inspections can be conducted more efficiently with minimal downtime, increasing overall productivity and reliability.