Service Tips -- Engine replacement options

Why a new engine may be better than a new machine.

by Helen Hagan

Nothing lasts forever, including the engine powering your rental equipment. Sooner or later you will be faced with the decision to either purchase a replacement machine, overhaul or rebuild your existing engine or install a replacement engine.

|

|

A service technician prepares a Perkins 400 Series-rated long block for installation. |

|

| Perkins 1104D long-block replacement engine. |

|

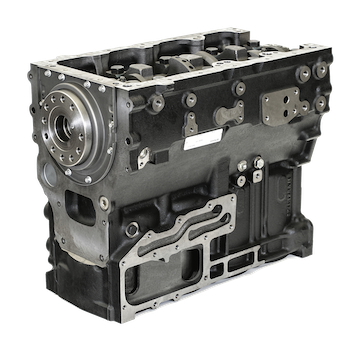

| Short blocks are another viable option for engine replacements. |

Of these choices rebuilding and replacing your engine is nearly always more cost effective than a new machine, but there are considerations before you decide which option is best for you.

Here are some of the questions you should ask.

What’s available?

Most engine manufacturers offer a range of solutions including re-build parts kits, short blocks, long blocks, remanufactured engines and new replacement engines. Each solution has its own pros and cons.

Parts kits: Unless you have the technical capabilities to use them and can afford significant downtime during a re-build, parts kits probably aren’t a good option for rental machines. If you have the time and ability, however, they can be a very economical solution.

Short blocks: A short block consists of a block with crank, pistons, connecting rods and the rear-end oil seal factory-installed. This choice is most appropriate when the rest of the engine is in good condition. A short block makes the most economic sense when the existing block has been damaged beyond repair but the rest of the components are in good condition.

Long blocks: A long block is a short block with at least the cylinder head and temporary top cover installed. Beyond that basic configuration, long blocks are available all the way up to very close to a complete engine minus only the electrical components and any engine-driven accessories. For a large rental fleet owner or Original Equipment Manufacturer (OEM), it often makes economic sense to inventory a few long blocks that can be field configured for use on a range of machines.

Remanufactured parts, short and long blocks: There is a much confusion about the difference between a factory remanufactured part and a replacement engine. The differences are important.

A factory remanufactured part, short or long block is one that has been returned to “as new” condition by the OEM or a factory authorized facility. Reliability depends upon the remanufacturing processes and some new components, which require high precision such as injector nozzles, may be used in the remanufactured part to ensure high quality. Factory remanufactured parts and engines typically come with a manufacturer’s warranty; Perkins offers the same 12-month warranty on both new and remanufactured products.

Perkins sells remanufactured long and short blocks, but does not sell factory-remanufactured full engines.

Many independent shops also “remanufacture” parts and engines for re-sale. Obviously, the quality of the parts and components used and the technical ability of the shop personnel can be highly variable. While that is by no means a blanket indictment, it’s prudent to approach this option with caution and exercise due diligence.

Replacement engines: A replacement engine is a brand-new, factory-fresh engine built on the same production line using the same components as the original engine. It will come with the same factory warranty as the original.

Perkins, for example, offers more than 400 replacement engine options including engines configured to meet prior emission standards in effect at the time the equipment was purchased.

Emissions considerations

If it is possible to replace a failed previous-Tier engine with a current-Tier engine, Perkins will do so. In cases where a previous-Tier replacement is the only compatible option, Perkins will supply a previous-Tier replacement engine that meets applicable regulatory requirements.

Considering the greater complexity of engines meeting Tier 4 Final/Stage V emission standards, the option of re-powering older equipment with engines meeting earlier standards can be economically attractive.

Consider downtime cost

Uptime is money in the rental business and the quickest way to get a machine with a worn-out engine back into service is by replacing the engine with an identical factory-new unit. The mounts will fit, the connections will be in the right places and all of the brackets and mounting points for engine-driven accessories will be there.

When a machine is down with end-of-life engine issues virtually nothing, including ordering a brand-new machine, will be quicker than re-powering it with a new engine.

Cost-effectiveness

There are several ways to answer the cost-effectiveness question. From a pure cost of parts perspective, a re-build kit is probably the least expensive until you add in the cost of labor to install it. The same is true of long and short block-based re-builds. The cost and availability of technically competent labor is a significant issue. Looking at it from a return on investment (ROI) perspective, re-powering with a replacement engine can be very attractive. Giving a second life to a machine that is already depreciated makes economic sense, especially when the purchase price difference between the existing machine and a new one is taken into account.

Rental customers are buying uptime and most don’t really care about how old the machine may be, only that it performs. Delivering that performance for the price of an engine rather than the price of a machine and doing it with minimal out-of-service time an engine replacement requires is hard to argue against from an ROI perspective.

Change engine brands?

First, every international OEM has to account for the number of replacement engines shipped into the United States and the number of cores (original parts) exported.

There is a cost associated with this and it’s usually, but not always, covered by a core surcharge on the replacement engine. Perkins, for example, gives a 100 percent credit for returned competitor cores.

The second part deals with the physical interchangeability of the engines. This requires an engineering analysis to compare mounts, connections, aftertreatment locations, accessory placement and other factors. There is a cost involved and some engine suppliers also pass it on to the customer while others, including Perkins, do not.

Weigh the pros and cons

Speak to your local engine distributor. Improving ROI by extending the life of assets is a good argument in favor of a replacement engine. Perhaps that’s why it’s a rapidly growing trend in the rental industry.

Helen Hagan is the aftermarket product manager at Perkins.

This article originally appeared in the July-August 2019 issue of Pro Contractor Rentals magazine. ©Urbain Communications,LLC. All rights reserved.