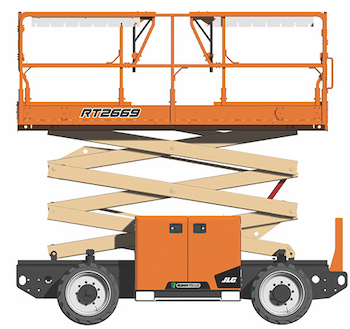

Rough-terrain scissor lifts

JLG’s new line features advanced LiftSense and QuickLevel Advanced technologies.

A new generation of rough-terrain (RT) and electric rough-terrain (ERT) scissor lifts fro JLG is 69 inches wide, and come in 26, 33, 40 and 47-foot platform heights. All models are available with a diesel engine or battery power source and electric drive.

|

| A new generation of rough-terrain (RT) and electric rough-terrain (ERT) scissor lifts fro JLG is 69 inches wide, and come in 26, 33, 40 and 47-foot platform heights. All models are available with a diesel engine or battery power source and electric drive. |

JLG rough terrain scissors now feature an industry leading platform size for comfortable operation and ample room to bring tools and materials to the work area. The 47-foot platform height on the RT4769 and ERT4769 provide up to a 5-story work height, a feature that is becoming more important as open space continues to diminish and buildings get narrower and taller.

“Our new line of rough-terrain scissors are purpose-built with a focus on minimizing the job site pain points of our customers,” says Rafael Nuñez, senior product manager, scissor and vertical lifts, JLG. “The new ANSI 92.20 requirements necessitated changes to our existing rough terrain models. Instead of simply making these changes, we engaged with customers around the world to better understand their needs, then looked at market trends such as urbanization before deciding that a from-the-ground-up approach was required.”

All models within the new RT/ERT line come with several productivity-enhancing features as standard equipment. Both indoor and outdoor drive at height capabilities are particularly useful for warehouse construction, which requires installation of utilities at a fixed height across the length of a building.

LiftSense, an evolution of JLG variable tilt, monitors the weight in the platform and the machine’s tilt to determine the allowable work envelope. This new and industry-first feature notifies the operator prior to raising the machine how high they can elevate, removing the guesswork that often results in having to descend and try again.

QuikLevel Advanced allows the stowed scissor to level on a side slope up to 5 degrees with driving at full height allowed under certain conditions. This is especially beneficial when performing work at height along the outside of a building that has been graded for drainage at a consistent slope. A significant time savings is realized when compared to traditional leveling jacks which require manual adjustment.

Unique features on these scissors also include the industry’s first LCD platform control box. This intuitive display delivers a multitude of productivity, terrain, machine health and safety notifications to the operator during use.