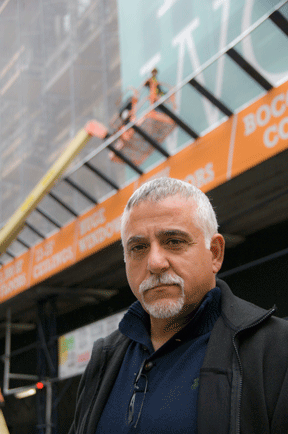

On top of his game

Owner rolls up his sleeves and gets involved

By David Wolff

The business of Alumaline Inc. is basic: install window units in large commercial buildings – hundreds and hundreds of them. The difference between profit and loss is slim. Make a mistake and the Whitestone, New York company is out of business. Owner Greg Samaras explains, “There’s an old saying, you can

Owner Greg Samaras explains, “There’s an old saying, you can

do 100 things right and no one remembers, but do one thing wrong and nobody forgets. It doesn’t matter how many projects we’ve done well, if we let down our guard and don’t satisfy the customer we’ll lose them. In order to maintain that edge we’ve got to be on top of our game every day and not get comfortable.”

Alumaline prides itself in knowing each project very, very well. A procedure might look simple on an architectural drawing, but suddenly becomes impractical at the job site. That’s when Samaras rolls up his sleeves and gets involved.

For example, nearly 95 percent of the windows in a project are interior-glazed and installed from the inside out. The crew comes to a shear wall and the process must be reversed. Now what do they do? They could take out the entire system for one window, or determine ahead of time that this window must be exterior glazed. The client appreciates not having to remove 30 panels to repair one.

“We always think ahead and find solutions,” Samaras explains. “I get involved because I can translate the customer’s ideas into practices that make the job installer-friendly. On paper, something may look good, but in the field it’s a different story. Our business is repetitive, so after some time we’ve gotten really good at it.”

Give clients 100 percent

In the mid-1980s, Samaras owned an automotive repair shop and was looking for a career change. A hunting buddy had a window business and invited Samaras to join him. The pair became subcontractors for top companies in New York City, doing window projects ranging from 1,000 to 5,000 units. A crew of 12 installed up to 150 windows a day.

By 2001, Samaras was ready to strike out on his own. He teamed up with a window manufacturer and they completed a job in Hoboken, N.J. That led to another project, and Alumaline took off. Today, 30 employees work on up to five projects at a time in the Tri-State area. Most are mixed use, a combination of residential and commercial. Within each job are multiple window systems, as well as architectural metal work, store fronts, railings and canopies. Because the work is repetitive, Samaras hones the process to a science.

“This is an extremely competitive business,” he says. “In our industry there are a lot of change orders. Some companies bid low and then work in the changes. We try to avoid them. Whatever the contract agreement said, we try to stick to it and make the customer happy. We don’t want to beat up the developer. We try to maintain a relationship with them.”

“We’re successful because I don’t wear a suit,” he continues. “I visit jobs every day and get down and dirty. We want to give 100 percent to the client.”

Rent larger equipment

Alumaline specializes in new construction using unitized curtain wall systems. In Manhattan, a typical project is all-glass. Windows are literally stacked on top of each other, spanning the building. Larger equipment is required to lift these heavy units and stack them floor by floor. While the company owns its light- to medium-duty hand tools, everything else is rented, including scissor and boom lifts, telehandlers and hoists.

“Even if bigger machines aren’t used a lot, they still have to be maintained,” Samaras says. “And, they take up storage space that could be used for inventory or deliveries. Purchasing is a cost that comes directly from profits, while leasing can be declared an expense. I’m saving money by renting because I don’t have to buy, maintain or store equipment. Our work is seasonal, and we might only use a machine for three months. The rest of the time it’s just sitting around collecting dust.”

Renting also allows Alumaline to react to the ebbs and flows of the work environment. Needs vary, so the rental schedule is flexible. Samaras talks regularly with Jack Georgakis of G.T. Rentals in Brooklyn, N.Y. (see cover story).

“Right now, I need a piece of equipment that maneuvers within a partitioned floor,” Samaras says. “It has to be 24 inches wide, and would also require a truck for transport. I only need it for three months, and Jack is helping me put together a deal. I might need one piece of equipment or three, and Jack has everything I need at his facility.” Samaras has been working with G.T. Rentals for about seven years.

Samaras has been working with G.T. Rentals for about seven years.

“They’re not necessarily a small business,” he says, “but we have a close relationship with the folks at G.T. Rentals. If the person I usually talk to isn’t in, whoever picks up the phone knows our account and can accommodate us. They know who we are. They even train my crew on how to use the equipment and then certify them. Some other companies are so huge that you don’t know who you’ll be speaking to from one day to the next. Renting a piece of equipment from a company like that can be a long process.”

Samaras also appreciates that the rental center delivers equipment and building supplies to job sites.

“G.T. Rentals is a one-stop-shop,” he adds. “Those guys are great. We rent exclusively from them. If they don’t have something they’ll get it for me.”

Meanwhile, Samaras will continue his reasoned approach to Alumaline’s future.

“We want to maintain a steady flow of business with slow, planned growth,” he says. “Once we meet our limit we’re not going to grow any more, we’re going to stay the same. I’ve been in business more than 25 years and two downturns in the economy seriously affected us. Projects were ready to go, but the banks pulled away. My strategy now is to be very careful.”

Originally published in the January/February 2014 issue of Pro Contractor Rentals. Copyright 2014 Direct Business Media.