The changing power scheme

Hybrid and dual-fuel systems are redefining tool and equipment power.

When Pro Contractor Rentals asked leading equipment manufacturers and experts about developments in dual-fuel equipment, several companies were pointed out that electric-powered units are already available.

|

| The JLG H340AJ aerial lift can work inside or out, using electric drives powered by batteries charged by an on-board generator and diesel engine. The engine/generator/battery combination lowers horsepower requirements and reduces emissions issues. |

Still others chose not to respond, citing work in development that they weren’t ready to talk about; others claimed they “weren’t the best resource to address this topic.”

In any event, several manufacturers had plenty to say and here’s what we found out.

Emissions and noise control driving change

|

|

Al Cervero,Senior Vice President, Construction, Mining & Utility, Association of Equipment Manufacturers (AEM) |

Transformative change is on the horizon for compact equipment, as technology continues to evolve and governmental regulations may require fleets to reduce emissions and noise.

Compact equipment will be the first to move to full electric power. Drivers behind this move include sustainability initiatives, a desire to gain a competitive edge and – in some cases – obtaining zero emissions incentives.

Full electric power uses less power, and therefore has less battery storage, so there may be some hurdles to widespread adoption. It all comes down to return on investment. If it costs equipment owners more, they need to see savings in operating costs over terms of ownership.

In addition, in requiring less power, there will be concerns regarding performance. Can operators use the equipment all day on one charge? What needs to occur to charge a piece of machinery at a remote job site? These questions, as well as those related to total cost of ownership and effects of governmental regulations, will determine pace of adoption.

Some equipment owners may require a lower carbon footprint while building. Certain states may require a percentage of a fleet to be zero emissions, or their regulations may require reduced emissions. These factors cannot be overlooked, and AEM is considering including this as an attribute in its statistics programs. AEM is also diligently monitoring state regulatory actions on this topic.

When it comes to the equipment rental market – both in general and as it relates to dual or hybrid power equipment – end user demand remains the primary factor to consider. As contractors see the benefits of going electric, they will voice their demands to rental companies accordingly. However, rental companies do not fuel equipment or pay its operating costs, so the benefits of electric are not really for them. Instead, their customers stand to benefit. Equipment will be made available at a higher rental rate, because it has to be.

The bottom line is this – attendees at coming trade shows can expect to see more dual or hybrid power equipment. Manufacturers are incorporating electric engines in a hybrid setup many different ways, to supplement diesel engines. This duplicates what occurred in mining shovels starting 50 years ago.

Advances in technology are sparking transformative change in the construction industry. How quickly these changes take place depends on a variety of factors. Ultimately, though, it seems to be not a matter of if, but a question of when compact equipment will move to full electric power.

Seismic shift coming

|

|

Erin McDuff, Marketing Manager, Allen Engineering |

|

| Propane is an alternative fuel that is readily available in most areas and can be used to power tools indoors. |

As we look to the horizon, it is hard to miss the coming changes to powered equipment. More and more manufacturers, including Allen, are looking into propane, dual-fuel and even battery alternatives for their product lines.

The biggest drivers for this are air emissions regulations and operator safety. The overall construction equipment market seems to be primed for a move to these alternative options, but it will be a few more years before it becomes a seismic shift. Lack of high-horsepower propane options and limited battery options are keeping this at bay for the moment. As more solutions are created and costs are reduced, things will begin shifting very rapidly.

Over the last several years, Allen Engineering made a push toward propane with its wheel buggy and its sales have continued to grow. Utilizing our AR16P propane-powered wheel buggy, a contractor can carry items inside without having to move product to hand carts or requiring any other additional equipment. This can mean great efficiency gains for a job site.

Following the wheel buggy, Allen Engineering also developed the PRO436DF walk-behind trowel that can be powered by propane or gasoline. Having this versatility allows contractors to use the fuel source that fits the job. If they are working indoors, they can switch to propane. Doing so will help them comply with air regulations and avoid the trip hazards associated with electrical cables.

By creating equipment that can be utilized in a variety of environments, Allen Engineering believes it has created great value for the rental market.

Economics play role in adoption

|

|

Jeremy Bailey, Air Products Manager, Doosan Portable Power |

While there is growing interest in using electrical power in construction equipment, diesel engine power will continue to be the predominant power source for most construction equipment.

No one has yet found the silver bullet to replace the diesel engine in compressed air or generators and as long as fuel prices remain relatively low, the adoption of dual- or hybrid-powered systems will be slow.

An area that has seen the most interest and progress has been solar-powered light towers. These units still must be able to perform to meet the needs of contractors, and sometimes the run time between charges isn’t long enough to cover a full shift, especially if the contractor is working longer than 8-hour shifts. Battery and fast-charge systems need to be developed. As the automotive industry develops better battery systems and more efficient electric motors and drives and the price comes down, there will be more of these units designed for use in construction. Until then, diesel engines win unless emissions regulations become even more stringent, which could drive up costs for more advanced emissions control equipment.

Similarly, the dual-or hybrid powered equipment will require additional training for maintenance, which can affect a fleet owner’s decision to switch over to new models.

In the end, it is the total cost of ownership that will drive adoption of hybrid equipment.

New models redefine “hybrid”

|

|

Zach Gilmor, Genie Product Manager, Terex AWP |

|

| The Genie Z-60 FE features electric drive and hydraulics powered by a battery that’s charged with an on-board generator or can be assisted by the generator for more power in outdoor applications. |

Compared to some other industries, aerial equipment actually has a fairly long history with dual/hybrid power sources. Simple “bi-energy” equipment has been commercially available within the aerial work platform industry for many years.

The next generation of hybrid machines, like the Genie Fuel-Electric (FE) hybrid, use advancing technology to improve performance, efficiency, simplicity and rental return on investment.

There are many drivers to this shift including technological advances and government regulations. Tier 4 in North America and Stage 5 in Europe regulations and an increasing number of local governments considering urban low emissions zones (LEZs) make hybrid equipment more attractive.

However, many rental owners of hybrid equipment are realizing the total cost of ownership benefits that come from a well-designed hybrid system. These units can simplify their rental business through the equipment’s superior versatility.

High-efficiency direct-drive AC motors that offer a 4 x 4 drive configuration have caused customers to take another look at the new generation of hybrid aerial equipment. These machines are very different from their simpler predecessors and bring significant values and benefits to rental owners and end users. The efficient drive system means the engine can be a much smaller and simpler power package. Even with these smaller engines, the new machines can be used to fulfill users’ needs for what was previously an electric or a diesel application. This is offering rental owners a new, simpler way to manage their fleets.

Perception is the highest hurdle to adoption. This is due in part to past experience with older generation bi-energy equipment and from our culture’s view of the term “hybrid.” With the introduction of the Genie FE system, Genie has changed user perceptions of hybrid equipment by offering no-compromises performance that has the power to lift, drive and charge the batteries simultaneously. It opens up new applications and new demand as rental owners and end users experience the benefits of true construction-grade hybrids.

These units are a good fit in rental operations because they are tough, reliable, simple to operate and easy-to-service machines that deliver high value for their money. Successful hybrid equipment wraps these characteristics into a package that also incorporates the versatility of indoor/outdoor performance. This will allow these machines to be rented everywhere that can range from on a finished floor in a convention center to a muddy, rough-terrain construction site.

Green projects require equipment rethinking

Paul Jensen, Marketing Communications Manager - Americas, Haulotte

In some parts of the world, environmental technology advances and adoption is being driven by government regulations. In North America, there may not currently be green regulations or zero emissions zones like what is seen in Europe, but there are a growing number of green projects that voluntarily choose to require alternative energy sources on site.

Even without regulations from government or job site rules, dual-fuel, hybrid, and electric-powered machines are slowly gaining market share each year. According to IPAF, hybrid and electric power sources have penetrated boom lift products growing from 18 percent in 2012 to a 32 percent share in 2017. Owners and users are becoming more aware of the advantages that come when a single machine can perform just as well outdoors on rough terrain as it does inside an enclosed building envelope.

The MEWP industry is beginning to take advantage of electric and hybrid technology advances that have been developed in other industries. Automobile and aerospace requirements have helped battery size and re-charge time shrink while also forcing capacity to rise. Power management software is becoming more effective, making duty cycles longer and giving greater insight into the operation of the machine. As technology improves in other sectors of the construction equipment industry, MEWP products are inheriting the benefits.

Price is a major concern for rental stores and needs to be overcome for contractors as well. Compared with traditional fuel systems, these machines are more expensive to acquire and should command a higher rental rate as well. The challenge is to demonstrate that the lower total cost of ownership and potential for higher utilization rates outweigh the initial investment. Designed with this in mind, the Haulotte HA61 LE PRO electric boom can reduce fuel use by 55 percent and reduce preventive maintenance costs up to 29 percent.

Another hurdle is overcoming some of the urban myths that already surround these technologies, especially batteries. Many in the industry believe Li-ion is the most eco-responsible battery technology and has the best performance but few understand it’s only the best battery under specific conditions and has an expensive disposal fee at its end of life. While lead acid is seen as an outdated technology, many may not realize it can outperform newer battery technology in certain conditions and is 99 percent recyclable. Recent advances in lead-acid technology have realized better shallow-cycle performance, doubling of cycle life and a 20 percent increase in energy density. Because machines like MEWPs already require a large counterweight for safety and stability, lead-acid batteries have the potential to outperform more recent technology while saving money.

Eco-friendly machines are sustainable for the environment and in the business plan as well. Future regulations could render entire existing fleets unusable. Investing now in alternative energy sources future-proofs today’s business as the construction industry prepares for a more aggressive environmental regulatory future.

Dual-power units offer clean, quiet operation

|

| Ignacy Puszkiewicz, Senior Director, Advanced Technology and Industrial Design, JLG Industries, Inc. |

Hybrid technology is defined as the presence of two separate primary energy sources – like fuel and electric batteries – that can be used independently or combined to achieve different operating characteristics for the machine.

As construction advances and the building becomes more closed or even sealed completely from the outside environment, battery-powered electric machines can provide a clean, quiet power source. The simplest solution is to use different machines for the phases of outside (engine powered) and inside (electric powered) building construction. There are shortcomings to this approach, especially in markets where cost of machine transport to and from the job site is a significant element of the rental cost.

Historically, the hybrid concept was based on a battery-operated boom lift with a direct electric drive. The electric machine was modified by adding an engine-powered generator to supply the average energy consumption of the machine in normal use. Machines designed like this follow the pattern of a series hybrid, where the engine-powered generator supplies electric energy that is connected in series with batteries. These batteries supply power to electric motors powering the drive and functions of the machine.

With MEWPs, a series hybrid is more efficient when compared with a hydraulically powered drive system and provides additional environmentally friendly features, most importantly a reduction in the risk of hydraulic oil spills.

Hybrid technology makes a very strong case for MEWP users, driven by the environment in which the machine will be used and very specific typical duty cycles. In contrast to other pieces of equipment, MEWPs are most productive when stationary and allowing construction workers to complete tasks at height; that is, working relatively short periods of activity followed by longer periods of idle. This is the ideal duty cycle for hybrids, allowing time to recover and recharge the batteries.

Looking ahead, we will likely see automotive standards for charger/power source interfaces adapted for use with MEWPs. This may be challenged by varying quality of power sources and lack of space to provide several large generators for a prolonged period. One solution could be battery exchange, but this was never adopted due to the constantly changing construction site environment. A possible solution may include modular charging stations that could include the integration of solar panels.

Finally, we can expect an increased trend toward fully electrically powered construction machines, especially construction MEWPs, but battery technology continues to be an obstacle; lack of charging infrastructure on construction job sites is also a problem. Solutions to these problems will be found. We are observing many technology and component development initiatives by equipment manufacturers and system suppliers that support both hybrid and fully electric machine development.

|

|

Douglas Hacker, Sales Representative, KATO Compact Excavator Sales |

Growing demand for rental units

There are many factors contributing to the world of electric construction equipment. With the restrictions that some construction job sites may have, there are times when the only option for demolition or general construction is with the use of electric-powered equipment such as in hospital renovations and the food service industry; and the list continues to grow.

Compact Excavator Sales (CES) have been providing electric excavators for more than 15 years to meet the needs of the construction industry, and this year it has introduced the battery-powered 9VXB mini excavator.

As restrictions on combustion engines continue to grow on certain construction projects, contractors are required to pursue a source for electric excavators. The rental market can meet the demand with Kato/Compact Excavator Sales electric mini excavators. Rental houses across North and South America are understanding the demand for these units and now carry the Kato/CES line of electric excavators.

Technology comes with a price. Although Kato/CES electric excavators are affordable, they still cost more than a diesel excavator. However, technology is advancing every day, so the cost will continue to decrease with advances in the industry.

Not all projects require the use of electric construction equipment, although more jobs are pushing in that direction. The majority of contractors can benefit with the option of renting one of the Kato/CES electric- or battery-powered excavators from their local rental store. This has been a growing request from our clients and now we can offer the option of either an electric- or battery-powered excavator. Because of the cost, contractors can’t afford to purchase a battery-powered excavator for just one job, so they will be much more likely to rent a unit.

|

|

Brian Astl, |

Improving batteries and LEDs drive light tower development

For light towers, the evolution toward dual or hybrid power is being driven by the increasing efficiency of LED lighting.

|

|

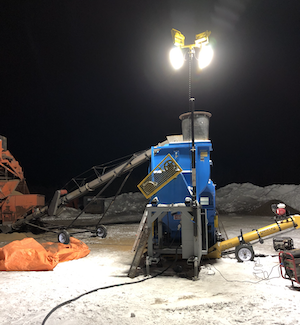

Hybrid light towers combine advances in LED lighting and battery technology allowing long run times, lower fuel consumption and charging flexibility with either an engine-driven generator, solar panels or extension cord. |

As LED chips have become more powerful, it is finally possible to create an LED array that matches the light output of the traditional 1,000-watt metal-halide lights on traditional light towers. Because the LED chips can now emit more light with less energy, they can emit more light for every watt of energy they use. This opens the door to dual/hybrid options such as generator/plug-in, solar/battery and other power configurations. The LED light source makes it possible to develop a dual/hybrid powered light tower that requires much less power to operate.

The rental market is very receptive to the idea of LED light towers that have the same output as metal-halide light towers but can be powered in multiple ways.

This dual/hybrid power option allows equipment rental stores to serve a greater range of applications. They make it possible to take a light tower inside without the concerns of generator emissions because the unit may be plugged into an external power source.

Similarly, an LED light tower can run off a silent generator as small as 1,000 watts or operate off a battery or external power. These applications couldn’t be properly serviced prior to the creation of dual/hybrid-powered LED light towers.

Technology continues to challenge hybrid light towers. Many manufacturers have released LED light towers with lighting levels below those of traditional metal-halide light towers, which has created the impression that that LED technology doesn’t put out as much light as metal-halide bulb, or doesn’t project light as far, so some customers reluctant to get into the LED light tower market. This is not an “LED” problem; it is a design issue. Educating the market to understand that not all LED chips are created equal will help to drive adoption of dual/hybrid LED towers.

The second technological hurdle is in the efficiency of some of the technology that enables more dual/hybrid options in the light tower market. While it is relatively easy to create a small generator/external power plug-in hybrid LED light tower, moving to a solar cell/battery hybrid is more difficult. The solar cell and battery storage efficiency, as measured in cost per energy generated/stored, is not yet at the point where a full-brightness LED light tower can be reliably powered solely by solar cells charging the battery.

To address this, many solar light towers add a backup generator for less-sunny days or if the battery doesn’t have enough storage to last the full shift. These hurdles will solve themselves as the solar and battery technologies improve, and as LED lighting requires less power for the same amount of light.

Today, dual/hybrid LED light towers are becoming a core product for equipment rental stores. They offer a full-brightness light tower that fit the needs of more customers and applications, so equipment rental stores are increasing their utilization and ROI on this investment.

|

|

Gary Crook, Vice President of Engineering, MEC Aerial Work Platforms |

Hybrid or dual-fuel units offer rental flexibility

There has been an elevated interest in direct electric-drive rough-terrain mobile elevating work platforms. Direct electric drive provides fast, powerful, quiet and smooth operation while producing longer operating times between battery charges.

A major factor driving this development is the cost and complexity of Tier 4 Final diesel engines. Rental companies want low cost of ownership, yet the Tier 4 Final engines have driven cost upward. It can also be time consuming to troubleshoot a Tier 4 engine, especially if it can’t be serviced by an in-house technician right away.

Direct electric rough-terrain machines are favored due to their lower cost and lower maintenance.

Recent years of experience with Tier 4 Final diesel engines have confirmed the fear of more expensive machines as well as complicated and restrictive troubleshooting and that is the single greatest driver in the rental market’s renewed interest in hybrid or dual-fuel options. Hybrid, as it applies to mobile elevating work platforms, is widely defined to be DC battery power with a small diesel engine that recharges the batteries when away from power. Dual-fuel machines run on gasoline and LPG.

While there is growing interest in the direct-drive electric units, the greatest hurdle to overcome is the historical perception of electric and dual-fuel machines. Electric machines are perceived to have poor duty life and poor rough-terrain performance. Another hurdle is that dual-fuel manufacturers have been inconsistent in their support in the market and have given the impression that they are not in it for the long haul. The best way to overcome these hurdles is to choose to do business with a company that can support your product during good and bad times.

Hybrid or dual-fuel options give rental companies flexibility in renting machines as both indoor and outdoor mobile elevating work platforms vs. renting a diesel-only or electric-only machine, thus better utilizing the hybrid or dual-fuel machine and saving overall cost. Some cities have noise ordinances between certain times in the morning and evening. Electric or dual-fuel machines are much quieter than diesel units and are the best options to use to stay below a specified noise level.

A hybrid option allows use of electric machines on remote jobsites that do not yet have power. If the project needs to be pollution-free when working indoors, the hybrid option allows outside recharging, which can also greatly extend the duty cycle where running the engine allows.

|

|

Brett Bishop, |

Corded/cordless tools part of the dual-powered tool movement

In October 2018, Hitachi Power Tools changed its name to Metabo HPT and launched its new 36-Volt MultiVolt platform of 36-volt brushless motor-powered tools. All tools in the platform can operate cordless by using the MultiVolt 372121M battery or can be operated as corded tools with the MultiVolt ET36A AC adapter. Cordless or corded: the user decides.

While new cordless tool models and their batteries continue to become more powerful, end users are still hesitant to switch to a full cordless platform. The MultiVolt platform addresses this hesitation. All MultiVolt tools are built with the power to withstand the most demanding tasks, regardless of being used as a cordless or corded tool.

Some job sites have temporary power, but what happens when tools are needed on another area of the site where power may not be available? MultiVolt is the answer. When power is available, the AC adapter is a perfect solution to save battery life and continue work with no downtime. Instead of dragging extension cords and relocating temporary power to the other ends of the site, MultiVolt gives the user the ability to swap the battery in and work off battery power with no sacrifice to power or performance. The MultiVolt battery and AC adapter provide a powerful, yet light weight solution to the end user for ultimate portability and productivity. Further, the MultiVolt battery is backward-compatible with the Hitachi and Metabo HPT 18V Li-Ion slide platform.

|

|

Andy Zuckerman, |

Technology evolves to improve consumer confidence

Perkins has certainly seen an increase in customer interest in alternative power sources. Alternatives to diesel engines, such as hybrids, are helping drive innovation and development in this area.

Hybrids and other alternative power sources are often thought of as being guided by an environmental or green agenda. But switching to a hybrid engine isn’t as simple as carrying over on-highway technologies. Machines are varied in design and operation, so we don’t see a blanket solution for all machine types.

This type of technology will move fastest into those applications where the economic benefits are clearest. Popular rental machines like micro-excavators, lift platforms, light towers and material handlers are all strong candidates for hybrid engines.

Perkins engineers take future product roadmaps and what that means to rental markets across the world into consideration. Perkins will be demonstrating its take on hybrid technology at the 2019 bauma trade show in Munich, Germany in April.

The greatest hurdles to adoption of hybrid or dual-power technology is consumer confidence in battery life and machine depreciation. Those must be overcome before there will be widespread adoption of these machines. Developing technologies are beginning to address these concerns, which will soon begin to increase consumer confidence. One example would be light towers that combine a diesel engine with battery storage and/or a solar panel to help make total operating costs much lower.

|

|

Alain Eav, |

Telematics makes hybrid units reliable

|

| What drove the development of this solar/engine-driven light tower was the need to eliminate light towers from running 24/7, having to refuel every 2.5 days and the need to decrease vehicles on the road at mine, construction and oil sites. |

About five years ago, the concept of solar and hybrid products was just emerging. RoviTracker was one of the first companies to roll out a patented hybrid product while 99 percent of the light tower industry was still producing light tower units powered by a diesel engine only.

Hybrids activate the lights based on a timer, photocell or by manual operation. Using the photocell or timer allows these units to operate automatically. Once the sun sets, the lights turn on and draw power from the batteries; once the batteries got below a certain level, the engine turns on and charges the batteries while the LED lights remained on. When the sun comes up, the lights turn off and during the day, the batteries were topped up by the sun. It’s very efficient.

What drove the development of this solar/engine-driven light tower was the need to eliminate light towers from running 24/7, having to refuel every 2.5 days and the need to decrease vehicles on the road at mine, construction and oil sites. These sites operate 24/7 and the last thing on anyone’s mind is to drive around and manually turn the lights and engine on and off.

The adoption is becoming increasingly positive. Attendees who were at equipment trade shows like World of Concrete, ARA and World of Asphalt in 2019 found more OEMs producing hybrid products.

The rental market will find these products to be very low maintenance. Some companies have products so efficient the engine runs only 2.5 hours per night while the lights are on for 10 hours. Refueling is a huge advantage for rental companies because these units may only need to be refueled less than 10 times a year.

Hybrid products were perceived to be fragile and complicated, unable to handle the harsh roads and environment. If that would be the case, they would prove to be a safety concern if it did not work by the time it reached final destination. Most companies have great mechanics who know diesel engines very well, but new technology like solar arrays, AGM batteries, solar chargers and inverters require additional to work on them.

Two key factors that help with widespread hybrid adoption are industrial-grade components and telematics. In the last five years, improvement to the solar modules have improved to better handle dust, impact and efficiency. Telematics allow solution providers to collect data on solar charging, the direction the solar modules are pointed, fuel percentage remaining, battery state for multiple banks, engine runtime and many other inputs and outputs. This means in realtime, a user can view this data and get alerts to decrease downtime.

This data makes it very easy to prove fuel savings, decreased downtime, travel and service time. The savings in travel and time is realized by fuel truck drivers. They can plan their routes instead of driving aimlessly checking fuel meters of every unit.

Hybrid light towers fit well in rental operations that require the equipment to be stationed for long periods of time such as at remote oil rig sites, long-term construction projects and mine sites. Although these sites are often difficult to reach, with the proper telematics device, the owner knows exactly what’s going on and makes trips only when they are alerted for refueling or there is an equipment issue.

|

| The Snorkel S3370BE adds bi-energy capabilities to the S3370RT compact diesel scissor lift with DC and diesel power. |

|

|

Matthew Elvin, CEO, Snorkel |

Dual-power models no longer niche products

The next big power development for compact equipment involves switching from larger, internal combustion engines to smaller engines and utilizing electric power as a supplement or using a smaller engine to supplement the charging on an all-electric machine. If a diesel engine under 25 horsepower can charge the batteries of an electric machine, it offers a significant cost reduction compared to the after-treatment expense required by larger engines.

Further benefits include clean and quiet operation while running on electric-only power and long operating life provided by the engine charging capability. In most lifting equipment, the weight of lead-acid batteries has proven beneficial as a counterweight, but as the cost of lithium power drops, the long life of lithium batteries will become more prevalent.

In smaller equipment where large amounts of counterweight may not be required and a charging engine is not realistic, the shift to lithium power is already underway, although the cost is still much higher.

The market for dual- or hybrid-powered equipment is maturing, driven mainly by contractor demand and job site-specific environmental guidelines and challenges. However, cost is the major hurdle to lithium power as an alternative to lead acid. The cost of electric power is becoming more attractive because of the lower electric motor pricing and the onset of more expensive Tier 4 and Stage V engines. This equipment really fits alongside the same capacity diesel-powered machines in a rental fleet. However, while they are no longer niche products, they still require an understanding of how their performance on the job site may differ from a diesel equivalent and how that affects the applications for which they are best suited.

This can present additional opportunities for rental companies by offering greater flexibility. For example, the Snorkel bi-energy powered compact rough-terrain scissor lift family can switch between diesel engine power and zero-emission battery power. This enables the lift to be used outdoors on heavy terrain or indoors to complete a fit-out. In this solution, the engine does not charge batteries, which means it is a true dual-power lift rather than a hybrid.

|

|

Lee Padgett, |

Emissions-free units attract attention

Takeuchi has been in the dual power market for more than three years with the TB216H hybrid dual-powered excavator. The dual-power option allows an operator to unload and travel to the job site using diesel engine power. Once in position, the machine can be tethered to a 480-volt 3-phase power source and switched to full electric mode for emissions-free performance. This is ideal for working in and around schools, food service facilities and hospitals.

The technology is still challenged by battery technology, which can be considered a hurdle to faster adoption. However, battery technology is improving and becoming less expensive and should drive a trend toward fully electric machines. Further, as more job sites restrict emissions output, the need for a dual power or fully electric machine option will grow.

From a rental center standpoint, there are many opportunities for rental houses to capture new customers that require a solution for emissions-free job site operation. Many end users do not have a need for a hybrid machine to be a part of their fleet full-time but need an emissions-free unit from time to time.

Training pays off with hybrid models

Alain Paré, Up Equip

|

| Hybrid units fit exactly where standard boom lifts or tow-behinds fit, but can also help workers get closer to the working area and can remove all types of restrictions that allow indoor use. Completely zero emissions, environment friendly, silent and reliable, the Easy Lift series of compact tracked lifts will meet all challenges in horizontal reach facing end users. |

What is an optional feature for most of our competitors has always been standard for Easy Lift. Up Equip does not develop power sources, combustion or electric/battery in-house because it is a lift company, not a motor company. Motors are required to power pumps and recharge batteries, and there are many manufacturers that can provide the, so Up Equip concentrates on refining design and developing new products.

The rental equipment market is craving models that can be used indoors and cordless. The lack of knowledge or availability of alternatives such as Easy Lift compact lifts from the rental industry leads to missed opportunities. The rental market hasn’t adopted the compact hybrid lifts yet. Only a few rental houses have been successful.

The main hurdle is still perception, even after all these years. The compact self-propelled hybrid tracked/wheeled lifts are still perceived as complicated, not user friendly and have a reputation as being unreliable and require extensive end user training. The rarity of compact lifts makes them intimidating for both contractors and rental houses.

There are also perceived as being fragile and hard to repair. Given the brands that are currently the most popular among rental operations, it is not surprising.

The inability for most technicians to effectively troubleshoot stems from the lack of time rental houses invest to train their techs. One example we have seen is a rental house that had 60 out of 68 units marked “down” in their system. Only an investment in training will prevent that.

Hybrid units fit exactly where standard boom lifts or tow-behinds fit, but can also help workers get closer to the working area and can remove all types of restrictions that allow indoor use. Completely zero emissions, environment friendly, silent and reliable, the Easy Lift series of compact tracked lifts will meet all challenges in horizontal reach facing end users.

Copyright 2019 Urbain Communications, LLC. All rights reserved. Contact curbain@urbaincomm.com for permission to reprint or rebroadcast all or part of this article.