New product news from bauma 2022

Manitou Group introduces four new aerial work platforms, two rotating telehandlers, and a fixed telehandler, four mid-height telehandlers at bauma.

|

| Manitou adds four new electric rough terrain models models. |

Electric MEWP platform range launch

With four new platform models, the group is accelerating the roll-out of its Oxygen low-emissions range. The 200 ATJe rough-terrain platform (working height of 65 feet) is now available with four-wheel steer for greater maneuverability and a basket that can now take 600 pounds of load, 72 pounds more than on the two-wheel drive version. The Total Cost of Ownership (TCO) is reduced with an almost 50 percent decrease in maintenance costs compared to the internal combustion version.

The range of rough-terrain electric telehandlers also welcomes two models, the 160 ATJe and 180 ATJe. With a working height of 52 feet and 58.5 feet respectively, these platforms also see their capacity increased by 72 pounds for a basket that can take a total weight of 600 pounds. There is also a second version named 160 ATJ+ e, with capacity significantly increased to 940 pounds. A range extender solution is also presented in the form of a removable generator common to all the machines, allowing for up to a week of autonomy.

As safety is at the heart of Manitou Group’s mission, the 160, 180 and 200 ATJe models come with a Safety Pack, protecting the operator and the site teams, as well as alerting fleet managers to any high-risk behavior.

The innovations in this pack include forgotten harness detection and detection of obstacles around the machine’s chassis. A lighting pack ensures the utmost safety for platform loading and unloading operations with a number of lights positioned on the platform to see and be seen.

A new version of the 120 AETJ platform has also been added to the industrial range. Presented as a sneak preview, this model has been entirely redesigned and is fitted with AC (asynchronous) motors providing comfort and flexibility of use. Extensive work has been done on the accessibility of the components, such as the pivoting battery containers and tool-free access for savings on machine maintenance. This new generation of industrial articulated platforms is equipped with the same diagnosis system as the rough-terrain range for rapid maintenance without the need for external tools.

|

| The MT 625e, with a capacity of 2.5 tons and a height of 19.5 feet, guarantees performance as good as the internal combustion version and is the same size. |

MT 625e electric telehandler

Manitou Group is also adding to its range of compact forklifts with the commercial launch of its first 100 percent electric compact telehandler. The MT 625e, with a capacity of 2.5 tons and a height of 19.5 feet, guarantees performance as good as the internal combustion version and is the same size. Fitted with a 25 or 33 kWh lithium-ion battery, this model reduces maintenance by 56 percent and drastically reduces the total cost of ownership for the user. Perfect for indoor or city center use or for renovating historic buildings, the MT 625e benefits like all the models in the compact telehandler range from the Safety Pack and the Harmony screen for safe and easy use.

Electric rotating telehandlers

|

| Manitou Group is presenting an electric version of the rotating telehandler models MRT 2260e and MRT 2660e from the recent VISION+ range. |

Manitou Group is presenting an electric version of the rotating telehandler models MRT 2260e and MRT 2660e from the recent VISION+ range. With a loading capacity of 6 tons for a lifting height of 71.5 feet and 84.5 feet respectively, these models enjoy the same performance level as the internal combustion models, even allowing simultaneous boom movements.

The 700 V/65 kWh lithium-ion battery ensures optimum use of these models, even in difficult climate conditions like in Northern Europe. To boost the range by an additional 4 hours, a second 700 V/65 kWh battery can be added. Users have a third option with a hybrid version of these models using a range extender. This configuration improves flexibility to make long journeys between two sites or to charge the battery on sites that do not always have electric charge points. There are also several charging mode options on these two models, with an on-board 11 kW charger for charging in 4 hours 30 minutes, and an on-board 22 kW charger that takes just 2 hours 15 minutes. An even faster solution is available to users with another on-board charger that allows charging in under an hour. Please note that the charging source must be 400 VAC. With these options, the Group is offering greater flexibility to operators according to their needs.

|

| Manitou is launching four new internal-combustion models -- the MT 735, MT 935, MT 1135 and MT 1335. -- with between 22.75 feet and 42.25 feet of lifting height for a lifting capacity of 3.5 tons. |

New mid-height telehandlers

To harmonize its mid-height range, Manitou is launching four new internal-combustion models -- the MT 735, MT 935, MT 1135 and MT 1335. -- with between 22.75 feet and 42.25 feet of lifting height for a lifting capacity of 3.5 tons.

The 35.75 feet and 42.25 feet models are available with two transmission versions -- torque converter or hydrostatic -- to meet the different needs of users. Two engines are also available for these same models, a 75 or a 100 h orsepower version. These telehandlers are equipped with the same dashboard as the rest of the range with a Harmony screen, as well as the option to move its control buttons to near the armrest.

These four models have a new cab for enhanced panoramic visibility, with a new windshield positioned even lower to better see the load when the boom is lowered and to make fitting of attachments easier. A new narrower, sturdier floating forks carriage has been designed as well to optimize visibility with the boom lowered. This carriage has been designed to be compatible with the 45.6 feet and 58.5 feet models. A new roof grille with sloping blades improves visibility of the load regardless of its position.

Fitted with a more spacious cab, these models remain relatively compact with an overall width just under 7/5 feet including the front stabilizers for models MT 1135 and MT 1335, making them ideal for use in tight spaces.

To ensure safe loading/unloading by truck, these four models can be transported in a container without having to remove the wheels. A fork attachment system is also available on these new models.

Innovations have also been made to reduce the total cost of ownership, with centralized lubrication at the back of the machine and quick rear access to boom components. All models are available with the Start & Stop option. The first models will be delivered by the end of 2023.

|

| The ultra-compact ULM (Ultra Light Manitou)/GCT (Gehl Compact Telehandler) telehandler meets the expectations of users who want an easy-to-handle machine that can be easily transported between sites. |

Ultra-compact telehandler

The ultra-compact ULM (Ultra Light Manitou)/GCT (Gehl Compact Telehandler) telehandler meets the expectations of users who want an easy-to-handle machine that can be easily transported between sites.

With a transportable weight of less than 3 tons, this model can be loaded onto a trailer with a GVW of 3,500 kg. At under 5 feet wide and 6.24 feet high, its dimensions are among the most compact on the market, making it easy to use in tight spaces, and particularly for entering buildings or maneuvering on renovation sites for handling pallets of concrete blocks or bricks.

The ULM/CGT is available in two versions, with a lifting capacity of 1.25 tons and 1.5 tons respectively and a lifting height of 14 feet. For increased safety, the visibility at maximum height has been optimized.

|

| With 12 new models, Manitou Group has extended its range of articulated loaders, which now comprises 22 models, all available under the Gehl AL (Articulated Loader) and Manitou MLA (Manitou Loader Articulated) brands. |

Articulated loader range grows to 22 models

With 12 new models, Manitou Group has extended its range of articulated loaders, which now comprises 22 models, all available under the Gehl AL (Articulated Loader) and Manitou MLA (Manitou Loader Articulated) brands.

These new products offer a load capacity ranging from 1680 pounds to 1.5 tons for a lifting height of between just over 8 feet for a short arm and 10 feet for a long arm configurations.

Series 2 and 3 models are equipped with a 25 horsepower Stage V engine, and series 4 and 5 with 48 horsepower engine. The complete range makes it possible to respond to very wide-ranging demands, with the largest of the articulated loaders providing a nominal load capacity of up to 3.3 tons.

New models have been specifically designed for construction (AL 320/MLA 3-25 H-C and AL 420/MLA 4-50 H-C) for handling pallets of materials on urban sites where compactness is a must. The Manitou MLA 2-25 H and Gehl AL 230 models have a hydraulic motor on each wheel to make these small machines even more maneuverable in any environment.

To facilitate the movement of these loaders between different work sites, the models are also transportable on a 4.2-ton GVW trailer. The weight ranges from 1.5 ton for series 2 to 2.6 tons for series 5 models. This advantage allows Manitou to adapt to the constraints of rental companies and tradespeople who move material-handling equipment very frequently within a very short time frame.

|

| The new MHT range has been designed to handle heavy and bulky loads on all types of terrain. |

New range of heavy load telehandlers

The new MHT range has been designed to handle heavy and bulky loads on all types of terrain. With capacities from 9 to 33 tons, for a working height of up to 39 feet, performance has been greatly improved. Ergonomics have been enhanced with a comfortable and easy-to-reach operator's station with wide, non-slip steps, a large door and the Easy Step floor cut-out allows safe cab entry and exit.

The new Manitou JSM joystick now incorporates a capacitive system for automatic and precise detection of the operator's hand for safe working.

The new MHT-X 11250 mining version with a lifting height of 35.75 feet for a maximum load of up to 25 tons. This versatile model has been designed for safe handling of heavy, bulky loads, particularly for mining maintenance activities. The ergonomics have been improved with a comfortable, easy-access driver’s cab with wide non-slip steps and a wide door.

|

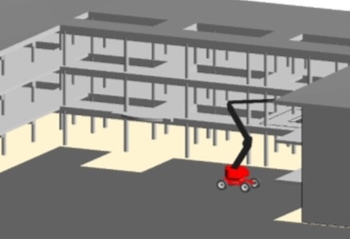

| BIM architects, modelers and designers can easily introduce Manitou machines into their work environments during construction projects. |

New modeling tool

To continue developing its range of services, Manitou Group is launching the modeling of its Manitou products for the construction market. Available worldwide in French and English in the Building Information Modeling (BIM) library via the manitou.com website.

BIM architects, modelers and designers can easily introduce Manitou machines into their work environments during construction projects. This modeling provides users with a totally immersive experience, helping them to make decisions and streamline costs.

This database is free of charge and easily accessible: just create an account to access all the 3D models.

|

| Manitou's Reviv'oil system has the ultimate aim to avoid machine downtime and thus reduce the user’s total cost of ownership. |

Reviv’oil service

Manitou Group is launching a new program intended to prevent hydraulic breakdowns. This program, named Reviv’oil, involves filtering the hydraulic oil.

To facilitate this, all latest-generation machines (with a capacity of more than 12.5 gallons hydraulic) have a predisposed tank.

Easy to implement with special tooling, this service is carried out in the maintenance shops by engineers from the Manitou dealer network.

The ultimate aim is to avoid machine downtime and thus reduce the user’s total cost of ownership.