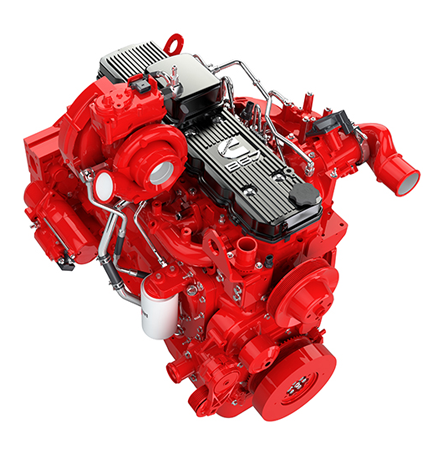

Cummins EGR-Free Engine Line Introduced

Cummins revealed a new generation of ultra-low-emissions engines spanning from 100 hp to 430 hp designed to meet 2019 European Union (EU) Stage V emissions regulations with simpler, EGR-free architecture and Single Module aftertreatment technology. The company introduced the engines at the recent Bauma event in Munich, Germany.

The newly-named F3.8, B4.5, B6.7 and L9 engines offer 10 percent more power and almost 20 percent more torque, averaged across the range, than their Tier 4 Final equivalents.

The newly-named F3.8, B4.5, B6.7 and L9 engines offer 10 percent more power and almost 20 percent more torque, averaged across the range, than their Tier 4 Final equivalents.

"Removing Exhaust Gas Recirculation (EGR) allowed us to realize the full potential of the engine for Stage V without increasing displacement size. Our 12-liter engine already pointed the way forward for a successful EGR- free design at Stage IV, so we were able to cascade this simpler approach down through the power range. No EGR also means there is less to cool, which will help lower the cost of OEM integration," said Jim Fier, Cummins Vice President - Engineering, speaking at the Bauma engine reveal.

Improvements to fuel efficiency will result in the overall fluid cost of the new Stage V engines reducing by 3 percent on average depending on application, compared to those of Stage IV. The engine operating costs will be further reduced with an achievable 1,000-hour oil change interval, twice as long as the current 500 hours.

Smarter electronics will bring Start-Stop technology imbedded in the engine management system, offering the potential to realize fuel savings of between 5 percent and 15 percent, corresponding to the amount of equipment idle time. Cummins Stage V engines are enabled for wireless connectivity, ready to deliver instant, expert engine diagnostics over the air so operators can maximize the uptime availability of their equipment.

Power Leap For Stage V

The 4-cylinder F3.8 and B4.5 engines show increased power and torque for Stage V, providing opportunities for OEMs to downsize engine installations. The 3.8-liter moves from 130 hp at Stage IV up to 155 hp at Stage V; the 4.5-liter jumps from 173 hp to 200 hp. Peak torque of the F3.8 increases by more than 20 percent. The B4.5 has an 11 percent increase.

At the smaller end of the Tier V range, the 4-cylinder F3.8 will be available at a 74 hp rating, allowing the opportunity for machines to downsize their engine installation without any loss of torque performance. The F3.8 will offer the benefit of a highly compact, engine-mounted Cummins DPF without the need for SCR, making that rating particularly suitable for rental equipment.

For both 4 and 6-cylinder engines, the substantial increase in performance is applied across the full engine speed rpm range. This makes the Stage V engines more adaptive for different machine-load demands, available either with high power at high engine rpm or high torque at low engine speed rpm. Combined with smart electronic feature sets and calibration shaping, this means that every application receives the ideal performance curve for the specific operation of the machine.

The Cummins Single Module for Stage V combines DPF, SCR and urea-dosing technologies in one module, providing an up to 50 percent reduction in envelope size and a 30 percent reduction in weight compared with those of Stage IV exhaust aftertreatment.