Service Tips -- Eliminate the pain

Using data to develop better business processes.

by David Swan

When an operation looks at construction processes for service, maintenance, and logistics, there’s a common goal of increasing efficiency and reducing operating costs. As these processes become more effective and more efficient, there wil be decrease in machine down time and an increase in true working time, which leads to increased profitability for the rental company, and the contractor/end user.

|

| Skyjack experts first looked to where an OEM can add significance to the telematics value proposition. From the start of the Skyjack journey to the eventual introduction of the Skyjack Elevate telematics system, it became clear to our engineers that a simple reseller of telematics would offer Skyjack customers minimal benefit |

The main cause of pain points around service, maintenance, and logistics is often related to lack of information. Sometimes that’s because the information isn’t available. For example, a service technician on the phone who can’t physically see the machine that’s down on a work site.

Sometimes the information is available, but business demands don’t allow the time to hunt it down. For example, rental yard staff not having time to test a battery before a machine is put out on rent. Many times, the information could be available, but there’s a cost and/or time barrier that prevents us from accessing it. For example, a critical service window on a combustion machine gets missed because it has been on a remote site for months.

Telematics data help. It provides the missing information and eliminates gaps in visibility that decease profitability.

Generic data limits actionable insights

Telematics data can make the rental industry more profitable and eliminate the pain points related to key processes in the rental business and on the work site, but only when it can access the right data.

For data to be actionable, it needs to address to a specific problem and be easy to access. A trend we’ve seen in telematics across the board is trying to provide the most data, or a generic data set, rather than the most important data.

There are two challenges this approach to data creates that prevent it from being actionable:

Challenge of Quantity. If more time is spent sorting through the data than the efficiency it creates, won’t drive profitability.

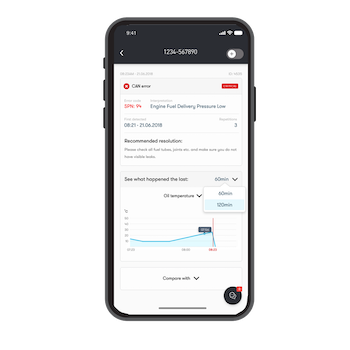

The more is better mentality creates a scenario where you may not be able to get anything out of the data at all. For example, combustion engines have hundreds of parameters available to be broadcasted, many of which have little relevance to a troubleshooting service call from a work site. If a technician has to sort through all those parameters on a screen, it’s likely going to take too long to find the important data that can solve my problem.

Therefore, the key is to limit the amount of data exposed to the technician on a specific machine type, and make that data is intuitive and easy to access. Optimally, make it directly related to the most common service issues. If data isn’t simplifying, then it’s not doing its job.

Challenge of Quality. Having high quality data, or the most important data, for every machine type is critical in being able to add efficiency to construction rental processes.

From the early stages of telematics adoption in off-highway equipment, the standard data provided for all machines in the fleet was hours and GPS location. This data helped with theft prevention and service scheduling on certain types of machines. However hours and location data points aren’t relevant to the top service issues for the majority of machines in the rental fleet.

The available data points need to match with the most common issues with each machine type. If a customer is calling in to report that an scissor lift won’t operate, hours and location won’t do anything to eliminate the gap in visibility for the service technician. Hours and location have no connection to any of the most common service issues that impact electric scissor lifts. The technician will likely be better off asking the operator questions rather than looking at generic telematics data.

The quality of data can be measured by its ability to directly solve existing construction rental problems. High quality data is required to eliminate visibility gaps, increase efficiency and create profitability.

Create the most important data

To create high-quality data and provide the most important data, it’s critical that the direction comes from the construction rental company and the end user. Any machine type in the rental fleet has a series of pain points related to user familiarity, service, logistics and other factors. These pain points drive service calls, delivery and fulfillment issues and cost the industry significant amounts of money.

If you ask a rental service technician, “What are your biggest issues on a combustion-powered boom lift?”, without hesitation you’ll get a list of three or more issues that they encounter most often.

Taking those three or so issues, ask: “What data, if you had it, would prevent that issue or reduce the time to resolution for the end user?” Their answer tells what would make high quality data for that machine.

The same process can be followed for other roles in the rental process, such as rental desk staff, logistics manager, fleet manager, which can identify other high-quality data points that help eliminate pain points related to different functions and processes in the business.

If high-quality or actionable data is data directly addresses existing industry problems, then the process to create that data needs to come from the industry itself. This process ensures the data available isn’t more than what’s needed, and is relevant, impactful and actionable.

How OEMs can help

Skyjack experts first looked to where an OEM can add significance to the telematics value proposition. From the start of the Skyjack journey to the eventual introduction of the Skyjack Elevate telematics system, it became clear to our engineers that a simple reseller of telematics would offer Skyjack customers minimal benefit.

Skyjack developers built the process the Elevate system so the OEM plays a critical role in delivering a telematics solution that has the maximum impact on the construction rental business. The OEM is in a unique place to create high-quality data points that have impact. Its close relationships with customers and industry practices, along with its ability to engineer the machines and hardware that report and transmit data that solves problems puts OEMs in the perfect position to deliver real value.

Skyjack developers have created and executed the process of creating high-quality data because our experts deal with rental companies’ service personnel daily and support them with our own service department. This gives us the ability to ask our service department, our customers and their service departments. Skyjack experts have asked end user what are your biggest pain points for this machine and asked them what data what would help eliminate those pain points.

Skyjack experts took that input to the engineering team and had them develop ways the machine could report the data most important to our customers. It’s been successful because in the beginning, the Elevate program was product driven by customer knowledge and shaped around their business goals.

OEMs have a special perspective because sit in the middle of customers, service departments and the the engineers and telematics providers. Having expertise and a close connection to each of these groups allows the team to engineer data points fairly quickly that positively impact our customers businesses from day one.

David Swan is product manager of Technology and Innovation at Skyjack.

This article appeared in the September-October 2019 issue of Pro Contractor Rentals magazine. © 2019 Urbain Communications LLC. All rights reserved.