Volvo's New Crawler Excavator

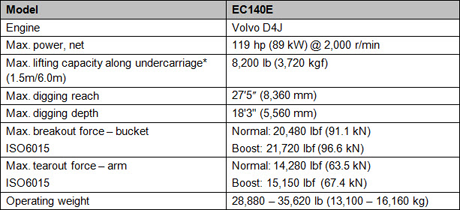

Equipped with a Tier 4 Final Volvo D4 engine, the new Volvo EC140E crawler excavator features a 5 percent increase in engine power and 10 percent improvement in fuel efficiency versus previous models. The increase in engine power and pump flow ensures responsive operation and travel speeds, as well as faster cycle times and improved productivity.

The hydraulics system, electronic control system and advanced ECO mode have been optimized to match engine power and reduce power losses. The redesigned main control valve and new software builds on the hydraulic control system, improving fuel efficiency and controllability. A boom float function allows pump power for boom lowering to be transferred to other functions, while the auto engine shutdown feature helps to reduce fuel consumption by automatically switching off the engine after a pre-set amount of time.

The hydraulics system, electronic control system and advanced ECO mode have been optimized to match engine power and reduce power losses. The redesigned main control valve and new software builds on the hydraulic control system, improving fuel efficiency and controllability. A boom float function allows pump power for boom lowering to be transferred to other functions, while the auto engine shutdown feature helps to reduce fuel consumption by automatically switching off the engine after a pre-set amount of time.

All machine interfaces — including the joysticks, keypad, panel and LCD monitor — have been ergonomically designed for optimum control and efficiency.

Along with the rear view camera, the EC140E also offers an optional side view camera to cover the visual blind spots.

The idlers, track links and upper and bottom rollers on the undercarriage are built to withstand tough terrain, while the X-shape lower frame enables balanced weight distribution, increasing stability and durability. The boom and arm design includes internal plates to help disperse the stress from high-pressure areas of the boom and arm.

The Volvo Lifetime Frame and Structure Warranty are covered under warranty for as long as the initial owner keeps the machine.

Guard rails and anti-slip steel plates help maintenance staff when checking the hydraulic tank, fuel tank and Diesel Exhaust Fluid (DEF), while the grouped filters can easily be accessed at ground level through a wide compartment door. The radiator, charge air cooler and hydraulic oil cooler can be accessed through a single door and are situated side-by-side on a single layer to maximize efficiency, reduce blockages and aid in cleaning.

State-of-the-art auxiliary lines provide the correct flow and pressure for special attachments such as mowers and grinders, shears, crushers and tilt rotators. A choice of one- or two-pump flow helps to maximize productivity and profitability.

An attachment management system allows the operator to pre-set and adjust the hydraulic flow and pressure for up to 20 different attachments, enabling the excavator to get back to work as quickly as possible after an attachment change.