Industry Outlook: Concrete equipment

Today's equipment for placing, finishing or repairing concrete is more ergonomic and productive than ever.

It’s no secret that good workers are hard to come by, and concrete work has always had the reputation as demanding, time-sensitive work that requires brain and brawn.

|

|

High power-to-weight ratios, excellent maneuverability and electric operation makes demolition robots an ideal rental addition for urban, indoor and confined space operations. |

|

|

Hydrodemolition robots can replace hand lances and jackhammers in many situations for vibration-free demolition that doesn’t damage rebar or diminish structural integrity. |

|

|

At only 31 inches wide, the Sherpa from Cratos easily fits through a standard interior door. Because it is battery-powered, it can safely be used indoors for a variety of concrete jobs, including preparation, placement and removal. |

|

|

Curb Roller Manufacturing’s roller screeds allow contractors the opportunity to take on additional work or equip a new crew and maintain a high-quality result. They are available in battery, electric and hydraulic power options. |

|

|

Rental centers can capture increased floor stripper, grinder, diamond tooling and vacuum rentals by learning more about various floor trends in their market. |

|

|

The Frost Fighter IDH1000 unit has a generator and includes two of Frost Fighter’s most powerful portable units. Built for remote concrete jobs, bridge work or locations with insufficient power and refueling access, it is also available with a light tower so the customer can rent an all-in-one package. The rental store can increase its rental rate and while carrying one product instead of separate machines. |

|

|

Lower-speed grinders reduce surface damage concerns. The lower speed 12- and 24-inch-wide units allow operators to get the job done right while minimizing the potential for surface damage. |

|

|

Electric carts and concrete buggies have almost zero maintenance to perform. The reduced maintenance costs and higher uptimes result in improved ROI across the board. |

|

|

When compared to similar gas units, battery-powered products generally offer easier starting, lower noise, less vibration and less heat. In addition, retail/rental centers will have an easier time teaching customers how to operate a battery-powered tool vs. a gas unit. |

|

|

Lind Equipment’s All-in-One Beacon LED tower is much cheaper than the traditional bulky metal halide generator towers. Its versatility and flexibility allow it to be rented out as a generator light tower, as an electric light tower or as a diffused light tower. |

|

|

MultiQuip’s fully hydrostatic LD6 ride-on trowel eliminates high maintenance service items such as belts, clutch drive systems, gearboxes, steering linkages and other components by providing a more reliable source of transferring power to the floor. |

|

|

Wheeled or tracked units? It depends on the terrain. Uneven or varied terrain will likely require a tracked vehicle, but smooth or paved surfaces will be able to use wheeled models. |

|

|

A breaker attachment opens up increased opportunities for rental houses to expand into additional demolition or foundation preparation work with their compact equipment lineup. |

|

|

IMER Group’s continuous mixer as well as the continuous mixer and pump machine is very popular in Europe and offers excellent ROI opportunity. |

Equipment manufacturers are striving to make equipment that for concrete demolition, placement and finishing easier and more productive to use.

Pro Contractor Rentals asked industry experts about next-generation equipment and how it is helping save labor and time and how it can fit in today’s rental market.

President, Lars Lindgren, Brokk Inc.

Robots break into concrete work

Concrete, like most other areas in the construction industry, is moving toward a more mechanized future.

|

| Lars Lindgren, Brokk |

Aging infrastructure plus a skilled labor shortage means there is plenty of work available, but not enough hands for traditional tactics. On the concrete removal side, particularly, contractors also need to find solutions that offer more precision because many infrastructure applications require shallow removal rather than full demolition.

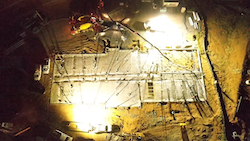

Add increased safety and environmental concerns, and you’ve got a market ripe for mechanized and robotic solutions. For heavy-duty demolition applications, remote-controlled demolition machines are providing increased productivity and limiting the need for heavy, high-vibration hand tools like jackhammers. High power-to-weight ratios, excellent maneuverability and electric operation makes demolition robots ideal for urban, indoor and confined-space operations. With a wide range of attachments, these machines can take on a multitude of tasks — from breaking to material handling — for a streamlined job site.

Hydrodemolition robots can go places people can’t, such as confined spaces or those with hazardous conditions to provide efficient removal or surface preparation on virtually any surface. In many situations, they can replace hand lances and jackhammers for vibration-free demolition that doesn’t damage rebar or diminish structural integrity.

When it comes to rental, centers that have embraced robotic solutions are already finding success with concrete contractors nationwide. For contractors offering diverse demolition services, owning their own robot isn’t necessarily cost-effective. In these situations, rental is an ideal solution. Many of the rental centers Brokk works with see repeat business from demolition contractors.

With the productivity of Brokk and Aquajet equipment, small crews can usually complete challenging removal tasks in a few days, maximizing value for the contractor and the rental center. With only a small fleet of demolition robots, centers can meet the needs of numerous customers.

In addition to increased productivity and safety, versatility ranks high in what customers are looking for from equipment. Being able to do more with fewer machines – and smaller crews – is important as concrete contractors stretch their operations to take advantage of as many opportunities as possible. Demolition and hydrodemolition robot manufacturers like Brokk and Aquajet are stepping up, providing high-tech, highly adaptive equipment that allows contractors to take on numerous applications with fewer machines.

For example, the Brokk 200 is a popular model with rental centers for the versatility it provides on the job site. It packs the power of a 3-ton Brokk machine into a 2-ton package, delivering 450 foot-pounds with each blow of the 650-pound hydraulic breaker. It also features Brokk’s SmartConcept system, which ensures improved performance and uptime. In addition to a breaker, contractors can use concrete crushers, drum cutters, shears, buckets and many more attachments, providing optimal versatility in any situation.

Aquajet’s Aqua Cutter 710V provides a similar high-tech solution for maximum flexibility. The hydrodemolition robot features cutting-edge technology that allows contractors to select the removal technique best suited to the application, whether that’s a set depth or selectively removing all damaged concrete within certain parameters. Additionally, the robot’s shape means contractors can remove the minimum amount of material when necessary. Plus, an extensive selection of attachments means contractors can tackle everything from surface preparation to removal around pillars and columns with one machine.

While demolition and hydrodemolition robots are not a new concept, there is still work to be done educating rental customers on the impressive capabilities of these machines. Rental centers can work with manufacturers to highlight equipment success in the rental space. For many contractors, rental is an ideal short-term solution for challenging jobs or experimenting with new services. The fact that most end up being repeat customers speaks to the value of the equipment for the contractor and for the rental center. Helping potential renters understand the capabilities and versatility of this equipment will go a long way to increasing ROI.

Founder, Alex Berg, Cratos

Newer tools for greater efficiency

Like the rest of the construction industry, concrete contractors are slow to embrace technological advances. But, as technology moves swiftly forward, contractors are finding that to be competitive, they must also increase efficiency by implementing newer technologies into the process.

|

| Alex Berg, Cratos |

For the most part, anything concrete-related has always been an extremely manual process, outside of the chemical composition of different products to create it, but technology is changing this. As a result, rental centers should be on the lookout for tools and equipment to assist in pouring, placing, finishing or removing concrete. Not only do machines make concrete contractors’ lives easier, but they also make the job site safer.

Several emerging trends will help concrete contractors overcome various challenges, improve overall work productivity and enhance the quality of projects. Intelligent equipment is going to make a significant impact on the concrete construction industry.

Rental centers can maximize their ROI by investing in versatile machines that serve a wide range of industries. For example, the Sherpa 100ECO with the Vacuworx P series vacuum attachment makes concrete removal a breeze. With a lifting capacity of up to 700 pounds, not only is it faster to remove concrete, but it is no longer the labor-intensive, arduous task it once was.

After years of lifting 100- to 150-pound blocks, the human body suffers significant damage. In fact, according to scientists, manual labor is linked to a greater risk of early death. The goal of a simple attachment like the PS 1 is to extend the number of years a contractor can keep up with the physical demands of manual labor. While a 25-year-old worker may be capable of handling the physical needs of concrete construction, he or she will not be able to do so in their 40s unless they can depend on innovative equipment.

Similarly, holding a jackhammer for an extended period takes a significant physical toll. However, when a contractor can use a Sherpa to carry a hydraulic hammer, the machine becomes a tool carrier and can complete a wide variety of tasks on any job site. The grapple bucket attachment and pallet forks are also excellent attachments that concrete contractors can use with the Sherpa.

At only 31 inches wide, the Sherpa easily fits through a standard interior door. Because it is battery-powered, it can safely be used indoors. That’s the technology that matters to a concrete contractor.

Concrete contractors need reliable machines that last all day, reduce manual labor, and keep workers safe. As a rental center, you want to invest in machines that solve this need. Understanding your customer starts with a conversation; what is it that could reduce their dependence on labor? What is taking the longest and creating more time delays? Understanding customers’ pain points will help rental centers offer the right tools and equipment to surpass the competition.

Technology moves quickly, and it is up to the rental center to keep their customers informed and make the best product recommendations. If you can provide valuable knowledge to your customers, they will keep coming back and trust you regarding the latest trends.

Seth Ulmer, sales manager, Curb Roller Manufacturing

Equipment expands contractor capabilities

Industries like concrete have the challenge of high turnover and a lack of available skilled tradesmen, in addition to ever-changing regulations, OSHA guidelines and fluctuating workloads. Contractors are looking for ways to maintain high productivity, reduce the risk of Worker Compensation cost increases and expand job opportunities. These factors are driving them to seek equipment that’s cost effective, versatile, easy to operate and easy to transport.

|

| Seth Ulmer, Curb Roller Mfg. |

Rental centers have an opportunity to meet this need with essential, efficient concrete tools that allow any size of operation to get to work fast and stay productive. This, in turn, will keep rentals up and customers profitable and coming back for more.

For example, with concrete screeding, if a rental center only carries A-frame screeds, they limit their rental potential and profit margin due to complex assembly and operating systems paired with cumbersome maintenance, storage and transport.

Carrying an easy-to-operate, versatile product, like Curb Roller Mfg. roller screeds, allows contractors the opportunity to take on additional work or equip a new crew and maintain a high-quality result. To provide flexibility for renters, Curb Roller offers battery, electric and hydraulic power options. One of Curb Roller’s newest screeds, the Batt Screed, is a lightweight option with no cords, hoses or fumes to worry about, offering unparalleled mobility and efficiency.

The unit is powered by a 60-volt Li-ion DeWalt FlexVolt battery. One fully charged battery can screed anywhere from 1,800 to 2,500 square feet and is ideal for any application from bike trails to shed floors. This flexibility and usability keeps renters happy while store employees appreciate the minimal maintenance for quick turnarounds.

While tool efficiency is always a top priority for customers, versatility is being demanded more across all industries. Customers are requesting options that allow them to do more work in more places and meet limited technical skill requirements.

Manufacturers are answering this with innovative designs that aim for more intuitive operation, rather than focusing purely on performance specs, as well as a push for electrification to meet environmental challenges and easing maintenance. For example, Curb Roller Batt and Eel screeds easily change rotational direction with the push of a button, where other screeds require users to disconnect and rotate the drive head.

By using a DeWalt FlexVolt battery to power the Batt Screed lessens downtime otherwise spent on tasks like engine maintenance or the logistics of coordinating an external power source.

Rental centers can also be a solutions provider for customers who may be looking to complete non-typical projects without taxing their time, crew and profit potential. For example, a flatwork contractor that pours parking lots or does street work could easily expand into curb and gutter work with the Curb Roller CM4000. This can remove subcontractor coordination and logistics to efficiently complete the work themselves, nearly 50 percent faster than traditional methods. With nearly 30 standard profiles in stock along with the ability to customize, Curb Roller keeps the process seamless for the rental house as well as the renter.

Customers just need to know the equipment is available, ready to rent and easy to use.

Chances are that these contractors are already coming in to rent or purchase other equipment and supplies, and our products provide a time saving and versatile solution that can connect them to more opportunities. By making the switch from alternative methods like A-frame or vibrating screeds, contractors can benefit from our low maintenance, easy-to-transport machines which become more accessible through rental vs. the commitment of purchasing. With these solutions and more, centers have a piece of equipment that can be easy to keep on a job site and off the rental shelf.

Tony Calcopietro, national account/export sales manager, Edco

Get positioned for flooring work

Coating, staining, exposing aggregate, sealing and polishing residential or commercial concrete floors has huge equipment rental potential due to many new easy-to-apply and durable trending floor options. Understanding a customer’s complete flooring project needs will drive increased machine rentals for floor strippers, floor grinders, edge or hand grinders, diamond tooling and vacuums. Existing concrete slabs may be covered with a soft floor covering, such as linoleum, vinyl tile, carpet or a hard floor covering such as ceramic tile or wood.

|

| Tony Calcopietro, Edco |

Stripping off either soft or hard floor coverings leads to necessary surface preparation steps to expose the beauty that only a concrete slab can offer. Residential home concrete slab renovation trends include upgraded garage floors, kitchens, entryways, living rooms, basements, man-caves, she-sheds, driveways, patios and workshops. Concrete slab spaces may require the removal of an existing floor covering followed by a floor grinder to achieve the proper concrete surface profile so one of the many modern and durable floor coatings, stains or polish can be applied.

Easy-to-apply topical concrete epoxy coating kits come with or without flake chips to provide a granite or terrazzo look. A deeper concrete grind will reveal large, exposed aggregate and can be followed up with a stain and seal to produce an attractive surface. A natural concrete salt-and-pepper look with a high grit pre-polish honing grind and seal may be desired.

Some higher-end trends include a highly reflective polished concrete look or an application of a modern metallic epoxy coating. These various concrete floor trends can be achieved by DIYers while the more difficult projects are completed by an experienced professional flooring contractor. Either way, rental centers can capture increased floor stripper, grinder, diamond tooling and vacuum rentals by learning more about these various floor trends in their marketplaces.

Grinders are now available in many power options. Units are available that run on 115-volt 15-amp service, commercial 230-volt power or even propane. Floor grinders now use quick-change slide on/off tooling plates, making it easier for the operator to match the tooling specific to the project’s needs. Grinders use simple leveling features to ensure all the tooling touches the floor for a smooth, non-gouged surface. Some grinders have become even simpler to use and easy to transport with fold down or removable handles. On Edco units, training information and operation videos can be accessed via smart phone using the Quick Response Code (QRC) decal on the machine.

Grouping common flooring machines together will drive increased ROI. Ask customers questions to understand the full scope of the project, then identify the various surface prep layers that need to be addressed and offer a complete project solution. A solution may include pairing up a floor stripper to remove the visible soft or hard floor covering followed up with a floor grinder to remove glues, sealers or surface imperfections on the slab. Offering hand or stand-up edge grinders gives the job a wall-to-wall finish by working the slab right up to the vertical edge. Always rent a properly paired concrete dust collector vacuum to ensure a clean, safe work environment.

Target homeowners attempting DIY garage floors, basements, patios, driveways, man-caves, she-sheds, or workshop renovations through social media and work with pro contractors to gain quality images or videos of their successful projects by offering discounts or credits for sharing photos/videos of your rental gear in action.

Nicole Clancy, president, Frost Fighter

Consider units capable of several tasks

One trend that continues is to use indirect-fired heaters to ensure the integrity of concrete, prevent carbonization and cure the concrete properly at the ideal temperature.

|

| Nicole Clancy, Frost Fighter |

Increased unit efficiency of units results in reduced fuel costs. Diesel-fueled heaters can be outfitted with a larger tank for extended run time so less time is spent refueling.

The Frost Fighter IDHQR models provide greater airflow and static pressure, which allows the user to heat a bigger area with more uniform airflow. These models have less amp draw and require less power on the job site. The Frost Fighter IDHQRM units have a fan control switch that allows the units to run the blower constantly while cycling the burner on and off as the thermostat calls for heat.

The self-contained Frost Fighter IDH1000 unit is equipped with a generator and includes two of Frost Fighter’s most powerful portable units. This is a great product for remote concrete jobs, bridge work or locations with insufficient power and refueling access. The unit is also available with a light tower, so the customer can rent an all-in-one package. The rental store can increase its rental rate and will only have to carry one product instead of separate machines.

Dennis von Ruden, president, General Equipment Co.

Remember ergonomics for operator comfort and productivity

Back-, neck-, shoulder-, hips- and knee-related injuries and pain is a large issue with the American workforce. Much of this is caused by repetitive motion disorders (RMDs) due to long-term wear and tear on muscles, ligaments, tendons and discs. Concrete workers are no exception to this, considering the lifting, bending, twisting, pulling and tugging they perform on a daily basis.

|

| Dennis von Ruden, General Equipment Co. |

Manufacturers are responding to this by developing equipment that helps keep workers off their knees to reduce physical stress and strain. Though a rental operator may not look at offering such equipment as a direct benefit to his/her business, a longer view is prudent. The healthier workers can stay, the more productive they remain, and the more they rent as a result.

Concrete is now considered a solid alternative to other floor covering materials due to its durability and aesthetics in industrial and commercial and even home remodels and new construction. This will expand the demand for tools for grinding and polishing concrete. Manufacturers have been developing more concrete polishing attachments, which should be a consideration to any rental operation looking to get more ROI out of the grinders already in inventory.

People are looking for grinding and polishing equipment that require minimal physical effort to operate. Renters are looking for less physical stress of pushing, pulling or maneuvering, and want to reduce the mental stress of achieving high-quality results in short order without damaging the surface that could lead to costly repairs that destroy profitability.

General Equipment has worked hard to make sure its machines match the job and the operator. Every job and operator is different; adjustable controls allow the unit to better match project conditions for better results; handles now fit an operator’s unique body type better for better control over the machine. General Equipment has put in many hours perfecting the weight balance of machines. This minimizes the physical effort one needs to apply to move/direct the machine and improves performance and reduces harmful vibration that can affect the operator.

General Equipment has deliberately focused on lower-speed grinders to reduce surface damage concerns. High-speed grinders are popular and in general, should be used by more experienced operators, but the lower speed 12- and 24-inch-wide units allow operators to get the job done right while minimizing the potential for surface damage. Plus, there’s less chance of losing control of a low-speed grinder when compared to a high-speed option. Lower speed units minimize bounce or shimmy, making them much safer to operate. General Equipment’s gimbaled head design follows contours and helps reduce vibrations back to the operator and improves performance, making these units a great rental choice for any customer, whether an experienced contractor or weekend warrior. The development of magnetic tooling systems, such as General Equipment’s recently introduced Magnetach technology that offers the choice between diamond segments, polycrystalline diamond (PCD) or tungsten carbide attachments, simplifies changing attachments that needs to be done several times during one job.

The breadth of selection available for tooling system attachments is growing. Users are finding that tools designed to work for certain types of applications work better than a one-size-fits-all.

To increase demand, promotion is key. People won’t rent what they don’t know is available. Find a method to regularly communicate with customers about the equipment and what it does well.

Training can help increase increasing demand and ROI. Make sure employees know what equipment is in inventory and the tasks they can handle. This is an ongoing struggle for rental centers as not every employee will have the same level of knowledge and interest in catering to customers’ needs as the proprietor. Regularly review equipment offerings with employees to assure they at least know the basics.

Too many times we’ve encountered rental centers where the employees didn’t even know they carried grinding equipment. It was back in the shop somewhere collecting dust.

If a potential renter can’t see your equipment – and employees don’t know they exist or what they do – there’s no way it can make you money.

Jeremy Rupp, marketing director, Granite Industries

Residential work requires different equipment

Nonresidential building projects are expected to decline as demand for commercial offices declines. On the positive side, residential construction projects have been on the rise and are expected to continue to rise.

|

| Jeremy Rupp, Granite Industries |

As a result, contractors are increasingly focusing on residential locations with new home construction and home additions/improvements. Rental shops should consider how their product line fits with the residential environment

One example would be promoting the use of powered wheelbarrows or concrete buggies. These carts are specifically designed to operate in tighter workspaces such as residential side yards and backyards.

As electric power becomes more popular, the quality and performance of electric-powered buggies and wheelbarrows will continue to increase. Bigger transaxles are becoming more available and Absorbent Glass Mat (AGM) batteries have substantially improved battery performance. In Granite Industries’ Overland Power Cart brand, demand for high-capacity all-electric power carts has reached an all-time high and resulted in two new models being released, the 950 series and 1400 series. Both feature high-performance transaxles and massive battery packs that are designed to last an entire workday. This combination gives confidence to contractors who may initially be skeptical of electric-powered equipment.

Electric power offers significant advantages in marketability when compared to gas-powered machines, such as zero emissions, no noise and a sealed drive system. For rental companies, there is almost zero maintenance to perform on the electric-powered equipment apart from remembering to plug the units in to charge. The reduced maintenance costs and higher uptimes result in improved ROI across the board. By offering high-quality electric-powered equipment, rental companies can expect to reach more customers and increase their long-term ROI.

Lloyd von Scheliha, product market manager, power cutters, Husqvarna

Battery-powered tools offer benefits

Battery-powered tools are one of the largest trends in the construction industry today. Three influential reasons we are seeing a push toward battery-powered tools include environmental impact, universal use and ease of use.

|

| Lloyd von Scheliha, Husqvarna |

Environmental factors are generally not the first thought to come to mind when you’re helping a customer select the right tool for a project, but there are many benefits to consider. Battery-powered tools reduce carbon footprint, reduce fuel and maintenance costs, and reduce the amount of equipment needed to get the job done.

End users can use battery-powered tools inside or outside and in tight spaces without the risk of hazardous fumes or additional power sources. Plus, there’s no need to stop and fuel tools on the way to the project site.

One way Husqvarna is striving to meet this trend is with the production of battery-powered, ergonomic tools that emit zero direct emissions and increase productivity. When compared to similar gas units, battery-powered products generally offer easier starting, lower noise, less vibration and less heat. In addition, retail/rental centers will have an easier time teaching customers how to operate a battery-powered tool vs. a gas unit.

The Husqvarna K1 Pace battery power cutter has advanced electronics and lower engine momentum made possible by a compact electric motor that incorporates an X-Halt blade-braking system. This system stops the blade and reduces the reactive force if a blade gets pinched, which helps reduce kickback. The easier-to-start and light-in-weight K1 Pace battery power cutter, available toward the end of 2021, will cut up to 6 inches deep and performs with lower noise, less vibration and less heat while getting the job finished faster.

Rental centers can increase revenue with the battery-powered tool trend by offering a one-stop-shop approach to customers by creating a full solution package, including ancillary equipment and accessories for machine rentals. For example, asking more in-depth questions about the customer’s project will assure you have a good understanding of the job and will allow you to suggest products that will make their project run smoother. Items may include the appropriate dry or slurry vacuum, water-dispensing system for dust control and blade cooling, or broad-application blades and core bits for concrete saws, power cutters or core drills. Understanding the customer’s needs, experience level and how the products will be used is key to assuring the customer is more productive at their job and keeps them coming back.

Brian Astl, president, Lind Equipment

Multi-purpose equipment gains interest

Lind Equipment has noticed a few trends in the concrete industry that has influenced the way it designs new light tower products. The concept of a flexible, versatile and multi-purpose piece of equipment should not be undervalued as it’s the current trend now and in the future on job sites. Workers, supervisors, purchasers and others are frustrated with being able to use only one product for one application. It wastes time on the job site and money purchasing numerous products for a single application.

|

| Brian Astl, Lind Equipment |

Lind Equipment has especially noticed this in the light tower market, which has always designed its products to be versatile. Based on market input, Lind has constructed a light tower that meets the needs every possible application.

The All-In-One Beacon LED tower has been high in demand for concrete-pour jobs because of its triple application. It can be used as a generator-powered light tower, an electric-powered light tower and as a no-glare diffused light tower.

The concrete industry sometimes works in residential areas at night, so the no-glare diffused light option would be ideal. Instead of having to rent out another light for that application, the All-In-One model enables them to use whichever application they need. This trend of flexibility and versatility allows rental facilities to increase rentals and triple their ROI.

With multiple power options, the customers can then choose and adjust the product as needed on the site. Generators are typically used to power multiple tools, but if they don’t need that, then use its AC power cord to plug into a 120-volt outlet instead of using fuel running the generator. The flexibility is key.

With multiple application options, rental centers can easily increase their ROI on versatile products because they will be rented out longer and more frequently. Versatile equipment is a great investment for rental facilities. There is rarely a downside.

By adding more of the same versatile product to their fleet, and highlighting the benefits and its versatility, the product will be rented out more for more applications and held onto longer because it can be used in a variety of ways.

This initial investment will be rented out more often and for longer periods so the return on investment just continues to soar. For example, Lind’s All-in-One Beacon LED tower is much cheaper than the traditional bulky metal-halide generator towers, therefore it has a cheaper cost upfront, but can be rented out at a higher rate. Its versatility and flexibility allow it to be rented out as a generator light tower, as an electric light tower or as a diffused light tower.

Torsten Erbel, senior director of product management, MultiQuip

Re-engineeered units reduce downtime, improve productivity

Trowel grinding equipment is quickly becoming a most requested rental item. Contractors have discovered the many advantages of this technique to improve completion time, with less labor and substantial reduction in investment. From simple flatwork corrections to restoration projects, trowel grinding has proven to be more cost effective than traditional methods.

|

|

Torsten Erbel, MultiQuip |

Today, rental centers can choose from many different systems on the market, so do your research to find the best system on the market to fill your needs. Consider the accessories you need to stock; a wide variety of grinding and polishing pucks or discs are required to achieve the desired results on a job site. Other accessories include cutting compounds, densifiers and slurry management equipment. By becoming a complete solutions provider, a rental center can increase rental revenue and ROI.

Concrete tools are exposed to extreme conditions in daily operation. The aggressive, harsh nature of concrete challenges many equipment manufacturers, rental centers and contractors to provide durable concrete products. The phrase, “concrete doesn’t wait” is a daily challenge for contractors placing and finishing concrete. It can dramatically increase costs and reduce revenue at rental centers when replacement equipment has to be delivered to a job site because of failed equipment.

Equipment experts at Multiquip/Whiteman analyzed common wear parts and maintenance requirements with the goal to provide rental centers and contractors with more reliable equipment while reducing maintenance tasks. The result of these efforts is MultiQuip’s fully hydrostatic LD6 ride-on trowel. This design virtually eliminates high-maintenance service items such as belts, clutch drive systems, gearboxes, steering linkages and other components by providing a more reliable source of transferring power to the floor. Features also include precise joystick steering, LED lighting and superior operator comfort for better visibility. Required maintenance schedules are greatly reduced, which allows rental centers to provide a better all-around product. These features also provide contractors with consistent reliability and less maintenance costs.

Other advances include more power options for contractors. Dual-fuel machines, utilizing gasoline and propane, broaden the appeal to contractors working inside buildings. Propane is rapidly establishing itself as an important alternative fuel with its impressive environmental benefits and inherent practical and cost advantages over gasoline. Propane has a remarkable safety record, due in large part to the stringent codes and regulations developed by the propane industry and the National Fire Protection Association. Propane has long been recognized as a “green” energy source. Nontoxic and insoluble in water, propane use can help cut emissions and protect the environment. Because it is released as a gas, it does not spill, pool, or leave a residue.

Updated, well-maintained fleets increase demand and ROI. Do not underestimate the need for accessories and supplies. While rates are competitive for unit rentals, accessories and supplies allow a rental center to increase ROI while providing a service item to the contractor, who may have not thought about the items he or she will need on the job. Review the job with the customer and all job requirements. It may expose additional rental opportunities or services you can provide, making it a one-stop service contract.

Be aware of industry trends, new regulations or requirements and update your fleet accordingly. Expand your rental center to offer solutions for the pro contractor as well as DIY homeowners. Many DIY projects are short term and invoice at book rates.

Rick Gramoll, director of sales and marketing, MBW

Push for fuel-less models

Trends of note in the concrete industry are fuel-less power and concrete polishing. There is no question that batteries are becoming more and more prevalent on job sites across the world and that technology is making its way to concrete pours as well. The ability to pour concrete in enclosed spaces without fumes is a huge step in the right direction for job site safety and productivity.

|

|

Rick Gramoll, MBW |

The polishing of new or existing concrete has also become a trend worth exploring for rental centers. Many home/business owners like the look and feel of polished concrete and are starting to search for contractors that can provide those services.

Safety, efficiency, ergonomics and green energy seem to be at the forefront of equipment advances. The push for fuel-less tools cannot be overlooked, but how equipment operates and more importantly, how that equipment impacts the operators, is just as important. With an aging workforce and scarcity of skilled labor, contractors are having to do more with less, which means using equipment that is not tough on workers physically and also gets the job done faster and safer. Doing more with less seems to be the way of the world and manufacturers are answering that call with equipment that can do just that.

For rental centers, being the first to offer a new technology in their area will give them a competitive advantage. Making their customer base aware that they offer these new technologies is important because customers can’t rent it if they don’t know it’s available.

The use of batteries means less maintenance which means more ROI. When it comes to polishing, wearable polishing pads can mean huge ROI for rental centers.

Kaitlyn Ingli, associate marketing manager, The Toro Company

Straightforward technology wanted by rental centers

As contractors look more closely at the concrete space, versatility and innovation are driving trends. Technology with a purpose has been big for rental stores and their customers, and that aligns well with Toro’s strategy as a key equipment manufacturer in the rental segment.

|

| Kaitlyn Ingli Toro |

In the past few years, we’ve seen the powered material buggy – also known throughout the industry as the powered buggy or concrete buggy – move from a niche machine for concrete placement in remote areas to a piece of equipment contractors are putting to work on a larger scale after realizing the inherent benefits of a workhorse like a material buggy on a job site. Being relatively simple-to-use machines, material buggies can help some contractors increase job site efficiency without a huge capital investment.

As more contractors demand material buggies, rental centers will need to not only increase inventory, but also carry more available options. Toro offers wheeled and tracked configurations as well as the groundbreaking Swivel Mud Buggy model.

Rental centers should work with contractors to understand how and where the machine will be most used. If they’re planning on using this machine on a large-scale construction site with uneven and varied terrain, a tracked material buggy may be the right choice. Alternatively, contractors planning to use this machine on paved, relatively consistent surfaces may prefer a wheeled option, which is historically less expensive than tracked units. Users should also factor in the capacity requirements based on their needs, considering the drive/dump power and the tub capacity. Being aware of new types of concrete innovations and equipment will help rental centers be a good partner to their customers when it comes to both inventory and selection.

The industry continues to demand equipment that make operators’ lives easier and more productive, and Toro units make that possible. For example, the new Swivel Mud Buggy model is built on the same frame as the popular Toro MB TX 2500 Tracked Mud Buggy, but the Swivel Mud Buggy has a redesigned tub that swivels 180 degrees, giving users the ability to dump materials anywhere in that 180-degree sweep. This innovation allows users increased versatility on the job site, while incorporating intuitive features that help drive productivity, such as an auto-return dump feature.

Rental store owners are meticulous and resourceful straight shooters. They know exactly how many hours they have to rent a machine before they will see a profit, and they can see through technological gimmicks or innovation for innovation’s sake.

Toro experts believe that providing solutions to the rental segment that will help increase demand and ROI means introducing solutions that come with a high degree of practicality. If the technology is too complicated, rental stores won’t see the ROI they need to justify their capital equipment investment in these units. If the technology is too basic, it’s easy for equipment to be commoditized and unable to differentiate from competitors. The sweet spot is when manufacturers can bring a good idea that solves an actual challenge for a good part of a rental store’s customer base. That includes providing an all-around solution that rental centers can leverage across segments. For example, the material buggy is an asset that offers productivity and versatility to a rental center, encouraging a faster ROI. Rental centers should look for versatile equipment that delivers innovation with a purpose to help drive ROI and increase demand from customers.

Travis Kiddde, Product Specialist, Doosan Bobcat

Breakers add versatility to compact equipment

A hydraulic breaker is a cost-effective way to turn your carriers into powerful and precise demolition machines. This attachment opens increased opportunities for rental houses to expand into additional demolition or foundation preparation work with their compact equipment lineup.

Many breakers can be configured to quickly swap between skid steer loaders, compact track loaders and mini excavators, making them extremely versatile. Advances in dust suppression technology, such as integrated water kits, allow contractors to meet OSHA job site requirements without consuming additional labor hours more easily.

Garry Haferbier, national sales manager, equipment division, IMER Group

Continuous concrete mixer and pump promises high ROI

IMER is constantly inventing and re-inventing technologies in the concrete industry. One product that has become mainstream in Europe is the continuous mixer as well as the continuous mixer and pump machine.

|

|

Garry Haferbier |

IMER continues to produce traditional concrete mixers, but IMER’s wide range of continuous mixers and continuous mixer and pump machines are recognized as very rental-friendly. IMER continuous mixers are designed to be easy to use, easy to clean, and easy to maintain, providing rental centers with a tremendous opportunity to provide customers with a great experience, cost-effective solution and a long-lasting and highly profitable machine.

The benefits of using continuous mixer and mix-and-pump machines are tremendous. First, they are no-mess machines. They have a dry material chamber and a separate water chamber. Once a project is completed, the user simply wipes clean the dry chamber, and hoses out the wet chamber. No need to spend time and effort chiseling or banging mixing drums. Second, the machines include iMER’s iDust Gate filtering attachment that attaches to a standard dry shop vac or HEPA vacuum and pulls the dust from the material into the mixing chamber, avoiding clouds of unwanted particulates.

Third, the units are job site friendly. They are lightweight, fit through standard doors, easy to maneuver, and are motor-driven. The electric motors provide more power when mixing and are easier to set up and operate on the job site. Most models require a standard 110-volt electrical supply. Fourth, there’s no guesswork. They include a water gauge to help monitor the continuous and accurate flow of water to the mixing chamber. Instead of adding buckets of water to a mixing drum, the user sets the water level once and then proceeds to add bags of dried material.

Fifth, the units have multiple uses and rental opportunities. They can handle many mixing materials and applications for homeowner and concrete professionals. They provide rental professionals the opportunity to sell the mixing and pumping of grouts, self-leveling underlayments, fireproofing, mortar, stucco, low-volume shotcrete and more.

Rental centers simply need to embrace the continuous mix and pump concept and become highly trained so they can provide demonstrations to their customers. Rental customers love to use tools that are easy to comprehend and easy to use but are reluctant if the tool appears to have highly advanced technology. Rental centers can be hesitant as well if the equipment seems to be complicated to operate, requiring more handholding and attention that erodes from the total ROI. IMER provides hands-on training, videos, and marketing materials to help educate rental customers and end users.

###

This article originally appeared in the July-August issue of Pro Contractor Rentals magazine. © 2021 Urbain Communications LLC. All rights reserved.