Rental Solution: Overseeding opportunity

Specialty tool appeals to landscape customers

By Linda Beattie

|

|

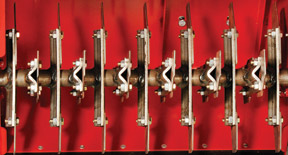

Above: A good rental solution is an overseeding machine that offers productivity and can meet specialized needs, such as slope seeding. Specialized units are far more likely to be rented than purchased. Below: Tight blade placement, as shown left on this Classen PRO HTS20, reduce the number of passes required to overseed, helping improve contractor productivity; a raised seed box (right) enhances quality by assuring seed falls at a consistent level in bumpy or uneven terrain. |

|

|

Overseeding is an additional, seasonal service that represents a growth opportunity for your landscape contractor customers. Having the right overseeder available – one that improves productivity – also offers opportunities for your rental business.

The majority of Classen’s overseeder sales are to rental dealers. In our experience, landscapers with larger commercial or community turf areas to maintain, or a significant number of residential accounts, will own and rent self-propelled, walk-behind overseeding machines.

Because overseeding is seasonal – spring and late summer/early fall typically are best – and because a professional-grade machine will cost in the $4,000 range, renting is a viable option.

A good rental solution is an overseeding machine that offers productivity and can meet specialized needs, such as slope seeding. Specialized units are far more likely to be rented than purchased. High-quality, professional overseeders offer additional advantages, including ease of maintenance and operator comfort. A machine that is easy for your customers to operate – and one that goes easy on your customers – will show its value in your rental fleet.

Comparing options

In reviewing machines, start by looking at the seed box. If the seed box is too low, during operation, moisture on the grass may cause seed in the hopper to plug the opening. A floating seed box is preferred, helping ensure that no matter how uneven or bumpy the terrain, seeds are planted at a consistent and optimal depth.

Select a model with a clear seed box lid so renting customers can see if the seed is clumping or if the box is empty. Some manufacturers also incorporate a seed dial and an instruction chart on the overseeder that allows operators to set the machine for the desired grass seed type so no seed is wasted.

When seeding on hills, an overseeder that allows depth control is ideal. Check the tires, too. Turf-tread floatation tires offer stability on hills, reduced soil compaction and zero tire ruts.

To provide the best seed coverage, the machine should have tight blade placement. Closely placed blades result in a thicker turf because there’s increased opportunity for the new seed to reach the topsoil.

Productive features

Quality shouldn’t sacrifice efficiency. Look for a manufacturer that incorporates productivity-enhancing features.

A hydrostatic drive, for example, provides variable speed in forward or reverse. With this, operators can adjust their speed for the specific job’s soil conditions. This allows operators to efficiently work in changing conditions and it reduces grueling muscle-work from manually having to push the machine.

When it comes to service and maintenance, features that simplify the process lead to a fast ROI. One area to reduce maintenance time is on the blades; some manufacturers design the blades with a cutting edge on both sides for double the service life. Also, look for greasable cast iron bearings on either side of the blade shaft because they last longer than nongreasable cast iron bearings and require minimal maintenance.

Classen’s HTS20 is a self-propelled unit with a hydrostatic drive for smooth power flow in forward and reverse gears. It has a 40-pound-capacity floating seed box that provides consistent seed coverage over bumpy terrain.

This higher-capacity seed box also enhances productivity because customers make fewer stops to refill the box. The HTS20 features tight blade placement at 13 rows per 20-inch swath. Tight blade placement reduces the amount of passes, enabling landscapers to complete more jobs in less time.

Linda Beattie is the marketing manager for Classen.