Rental Solutions: Pump it UP

Select the right hydraulically driven submersible pump for the job.

by Jeff Whittaker

Most rental companies carry dewatering pumps. Some rental companies have entire divisions dedicated to pump rental and carry a wide variety of pumps to handle many different applications.

|

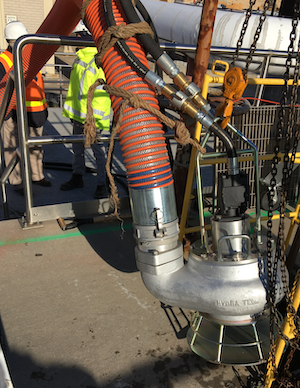

| Hydra-Tech offers a wide variety of pumps for specific applications. |

|

| Choosing the right pump for the job will help to make a rental successful; choosing the wrong pump for the job can be disastrous. |

There are also rentals companies that have a couple of electric submersible pumps for a homeowner’s flooded basement and a couple of gas engine-driven centrifugal trash pumps. As with any type of equipment in a rental fleet, the people working for those rental companies with broad pump offerings have to know which pumps are the right ones for the job. They must be able to take the customer’s requirements for their job, do the calculations for head, pipe friction loss and other factors, then select the right pump for the job.

One type of pump among many in rental fleets across the country is a hydraulic submersible pump. Hydraulically driven submersible dewatering pumps and the hydraulic power units that make them work provide greater flexibility and safety than an electric submersible pump, as well as greater head capability than a gas-powered trash pump.

One thing to keep in mind with these pumps is that like electric pumps, the hydraulic submersible must sit in the body of water from which it will pump.

Hydraulic submersibles do not expose operators to the potential risk of electric shock and do not require an electrician for set up as in the case of larger electric submersibles.

Hydraulically driven submersible pumps can be used in hazardous environments. Setup of a hydraulic pumping system requires only normal hand tools for the connection of the hydraulic hoses and discharge hose.

Hydraulically driven submersible pumps come in a wide variety of styles and sizes to cover a wide variety of applications. Choosing the right one for the job will help to make a pump rental job successful; choosing the wrong pump for the job can be disastrous.

Here are common applications for hydraulically driven pumps and selection criteria for each:

General-purpose dewatering This is a rather broad description that covers many

|

|

S6V 6-inch trash/solids dewatering pump with recessed vortex impeller for sewage bypass |

applications. It includes ballast/bilge pumping, construction job site dewatering, diver-controlled vacuuming and marine salvage, digester cleanout, mine/quarry dewatering, oil skimming and recovery, pond cleaning, sewage bypass and drilling/boring hole dewatering.

For general-purpose dewatering applications, pumps are chosen based on these parameters:

- What are the head and flow requirements?

- Will the pump need to handle solids, grit or sand?

- Is there a size restriction that the pump must meet, for example, fitting through a manhole?

The head and flow, to a great extent, will likely determine what size pump is required, although there may be some options between a few types and sizes of pumps.

Channel impeller pumps deliver greater head capabilities, so if the job requires overcoming significant head, it’s likely that a channel impeller pump is the best choice.

If solids will be present in the fluid that will be pumped, a pump with a vortex impeller is the best choice. Vortex impeller pumps are designed to minimize contact between the solids in the fluid and the impeller, which sits higher in the volute and out of the path of the fluid flow. If the job requires significant head capability and handling solids, a channel impeller pump is likely a better choice than a vortex impeller pump.

Hydraulically driven centrifugal submersible pumps typically come with discharge sizes of 2-, 3-, 4-, 6-, 8-, 10- and 12-inch diameters. With each increase in the discharge size, the pump itself gets larger. If the job requires getting the pump through a small opening such as a manhole, boat hatch or other restricted access space, choose a pump that will fit through the opening.

Low-head/high-flow applications An axial pump is ideal for very low head (40 feet or less) and high-flow applications with minimal solids. An axial-flow pump is like a straight piece of pipe with a strainer on the inlet, an impeller and hydraulic motor in the middle and a flange on the discharge end.

|

|

S6P 6-inch low head, high flow dewatering axial pump |

Because the impeller and hydraulic motor are in the middle of the fluid path and susceptible to whatever might be in the flow passing through, large solids such as rocks banging through the pump and impacting the impeller and motor and hydraulic feed lines can cause damage. If the job is draining a shallow pond for cleaning at a fish farm, doing dry dock, foundation and cofferdam dewatering, flood irrigation and even flood control, this is the right pump for the job.

High head applications Some pumps are designed with close internal clearances to deliver high-efficiency clean-water pumping. These pumps will overcome high heads up to and over 400 feet. However, solids and abrasives will ruin these pumps in a hurry, so it is important to prevent any rocks from entering the pump inlet and moving through the impeller.

High trash content applications Think of this category as bodies of water that contain trash that could clog the inlet of regular pumps – items like plastic shopping bags, rope, gloves, rags, safety glasses – basically garbage of any kind floating or submerged in the body of water being pumped.

|

|

S3SHR 3-inch shredder/high trash content dewatering pump. |

Although some solids/trash pumps could potentially handle and pass many of these kinds of solids, it’s better to select a shredder pump for this application. A blade and suction plate mounted to the inlet of the pump can slice and dice the solids into pieces that can pass through the pump. Some of the pump’s contact and cutting components are treated and hardened to offer wear resistance over the long haul.

High solids content applications For applications such as desilting and dredging, beach reclamation, filling geotubes or sand bags, sand plant pumping, diver-controlled vacuuming, drilling mud transfer/rig cellar dewatering, digester cleanout, grit chamber pumping, power plant water intake cleaning and slurry pumping, it’s important to use the right pump for the job or those solids will literally eat up the pump.

|

|

S3CSL 3-inch sand/slurry/high solids content dewatering pump |

Some of the specialty sand slurry pumps have components that are tungsten carbide-coated for extra wear resistance. Others have cast components that are made from high chrome iron, of which some are hardened, again you reduce the wear impact of the solids passing through the pump. Accessories such as a jetting ring and slurry gate are available for sand slurry pumps that will help to stir the solids into suspension.

|

|

S3SCR 3-inch high viscosity liquid screw pump |

High viscosity fluid pumping To pump molasses, refinery waste, latex or other high-viscosity fluids, a screw pump is the best choice. A screw pump, like the high-head pump, has a very tight tolerance between the volute and the impeller. The impeller is shaped like a screw and physically drives material through the pump like an auger.

Bore-hole/blast-hole pumping This application is typically a 4- to 8-inch diameter hole and uses narrow-profile hydraulic pumps that fit in them. They have a topside discharge and hydraulic connections so they will fit down a hole as small as 4 inches in diameter.

|

|

S3A 3-inch narrow profile bore hole/drill hole dewatering pump |

Blast-hole dewatering and drilling-hole dewatering are common jobs for these pumps, but they can be used anywhere there is a small opening. Generally, they deliver decent head capability.

Power considerations

The only other consideration that is true with all of these specific applications is making sure that the hydraulic power unit matches the power requirements of the pump.

Every pump has a maximum hydraulic flow and pressure input. This is typically where you will get the maximum performance out of a pump. When rental companies are buying for a fleet, they usually buy a system. A system would include a hydraulic power unit (HPU), hydraulic hose and one or more pumps that are matched to and will run with the HPU.

With the right equipment on hand, choosing the right hydraulic pump for the application will get your customer’s pumping job done right.

This article was written by Jeff Whittaker of Hydra-Tech Pumps and appeared in the July-August issueof Pro Contractor Rentals magazine. ©Urbain Communications LLC. all rights reserved.