Expansion minded

Hugg & Hall Equipment Co. looks to unfilled customer niches to expand rental opportunities

|

| Spencer Hale, Hugg & Hall Utility Services Manager. |

Sometimes, your best opportunities are right in front of you, but because of the busyness of everyday business, you fail to see them clearly.

That sums up how Hugg & Hall Equipment Company has built its market share and customer loyalty throughout the Mid-south.

Today, with headquarters in Little Rock and seven branches in Arkansas, three in Louisiana and two in Oklahoma, the company has built a unique and wide-ranging rental fleet.

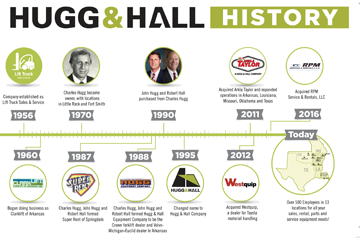

The original company started in 1956 as Lift Truck Sales & Service Corporation and in 1960, the company changed its name to Clarklift of Arkansas. Charles Hugg purchased the dealership in 1970, operating branches in Little Rock and Fort Smith.

In 1990, Charles sold the firm to John Hugg and Robert Hall and they renamed the business Hugg & Hall Equipment Company. Today, the company sells, rents and services equipment from Bobcat, Combilift, Crown, Doosan, Enersys, Extreme, Genie, JLG, Manitou, Sellick, Skyjack, Taylor, Terex, Toyota and Volvo. With more than 5,000 pieces of equipment in its inventory, its replacement parts in stock is valued at more than $6 million. To service the wide variety of brands across its 13 locations, Hugg & Hall has a team of 190 trained ASE-certified mechanics and more than 500 total employees.

|

|

Timeline |

A number of acquisitions has helped Hugg & Hall become one of the largest independent rental companies in the Mid-south. In 2011, it acquired Arkla Taylor, a dealer for Taylor Machine Works, then acquired Westquip, a Toyota material handling company in western Oklahoma. Hugg & Hall most recently acquired RPM Services and Rentals in Houma, Louisiana, which specializes in serving the offshore oil and gas industry with air compressors and the tools needed for sandblasting, painting, coating and other maintenance functions.

The company has found that construction equipment rental service and sales has become their largest category of business. Hugg & Hall also remains a big player in the material handling/forklift market and serves a wide industrial customer base throughout the region.

Continual growth

|

|

Industrial customers need service 24/7. This electric-powered portable air compressor backs up an air compressor in a food processing facility that went down at one of the plant’s busiest times. |

The positive growth in construction continues to drive a substantial portion of Hugg & Hall’s bottom line, however, it continues to look at specific market segments that aren’t well-understood or are underserved in the Mid-south, says Spencer Hale, Hugg & Hall Utility Services sales manager. One poorly understood area the company identified was the standby and portable power and power distribution needs of industrial and events customers.

“We are now putting more focus on industrial opportunities,” says Hale. “We have established a Utility Services division that offers temporary portable power for industrial applications. We are offering portable HVAC, supplemental air compressor and portable power generation to industrial customers,” he says.

Fine-tuning the wheel

“We aren’t trying to re-invent the wheel, we are just fine-tuning it,” says Hale. “All of the big rental companies are here as well as many good regional and local competitors. We are very competitive in our market, but are finding that we can offer the most value to our customers with our service offering and equipment availability.”

|

| Hugg & Hall’s main entrance to its facility in Springdale, Arkansas, mimics the company’s logo. It’s well-known in the Mid-south as a leading regional rental and equipment sales company. |

Hugg & Hall’s Utility Services division has been in place for just over one year and has seen excellent success.

On the industrial side of the business, customers often need equipment immediately to solve an issue such as a failed compressor or power shortage or outage. “We have the ability to move equipment quickly from branch to branch to meet our customer needs,” he says.

“Industrial customers are usually 24/7 operations, so when they have an equipment rental need, it’s usually causing downtime and they need the rental equipment right away,” says Hale. “They can’t wait a week or two. We focus on getting the equipment they need as fast as we can. That brings back many customers on future rentals because we got them out of a jam in an emergency.

“We have several people dedicated to delivery dispatch and we have GPS location devices on every truck. We know exactly where they are in case we have a pickup close by that needs to be expedited somewhere. That driver can swing by, pick it up and deliver it quickly,” he says.

|

| Temporary power and HVAC is one of the services the Utility Services Division offers. |

The Utility Services team soon realized that once they collaborated with customers and asked questions about their specific utility application, Hugg & Hall was able to provide an economical and reliable solution.

That philosophy has played well as Hugg & Hall continues to develop its Utility Services division. “I’d say our generator fleet is rapidly growing,” says Hale. “We realized we had a gap in our generators. The mid-sized units, in the 45 kW to 200 or 300 kW range, is where we have built our generator fleet. That covers most jobsites in this area of Arkansas,” Hale says.

“We have been growing our fleet of generators, and most recently, it has been Doosan generators in the 45 kW to 100 kW size range, to fill some holes in our fleet. With a greater selection of different sizes, we are more likely able to match the right generator to the application. If it’s oversized, it’s not the most economical unit for the customer; if it is undersized, the customer has problems and that means we have problems,” he says.

|

| Hugg & Hall is well known for its material handling rental and sales fleet. |

Hugg & Hall also has added custom power distribution panels to its product offering. These units, along with conveniently sized power transmission cords and spider boxes, helps them standardize their product offering and provide the right cord length for the application. “We talk extensively with our customers at the front end of the project to make sure we understand their power needs. Do they need three-phase power? At what voltages? How many amps are needed? Will there be power spikes from motor starting? We need to know that to correctly size the units,” he says.

“Through our new I-Line panel, we can provide power to multiple HVAC units off of one generator. It saves us from having to bring multiple generators for an event,” Hale says.

Secret sauce: flexibility

|

| These docking stations are installed at a local hospital’s urgent care facility to make portable, temporary generator connection fast and efficient. |

As a privately owned company, Hale says the firm is more flexible than many of its competitors.

“As we work with customers, they may bring up some equipment need they have and we are flexible enough to be able to get that equipment. Many times, it is something we haven’t even thought about renting and we can jump out there and buy it, if it makes sense from a rental standpoint. This helps us get the deals on the bigger parts of the business and we are able to keep our customers very happy.”

The Utility Services division has also found niches of need in portable HVAC as well as power distribution and specialty compressed air units. “Some plants are heavily using portable air conditioning units to help cool workers. We had units go out when the weather turned hot and they haven’t come back yet,” Hale says.

In other plants, Hugg & Hall has been able to meet customers’ needs who have had compressors go down in the busy season. “In this instance, we brought out an electric portable compressor that was wired into the building’s service. It has worked out well. It solved their concern about keeping a diesel-powered unit fueled.”

Hale characterizes Hugg & Hall’s rental equipment fleet as newer than its competitors, with an average age of 45 months. However, he also credits the company’s extensive training path as a key in making sure equipment is reliable and available.

Staff trained for service

|

|

Employee training at Hugg & Hall starts from day one with the firm. Many technicians are hired with some vocational training, but James (Lennie) Lennartz, Hugg & Hall’s trainer, says it is definitely an ongoing effort with all employees. |

Hale adds that its staff is well-trained for equipment maintenance and repair. Many have been with the firm for more than 30 years.

Employee training at Hugg & Hall starts from day one with the firm. Many technicians are hired with some vocational training, but James (Lennie) Lennartz, Hugg & Hall’s trainer, says it is an ongoing effort.

“We take new technicians from trade schools and sometimes from competitors and start with a 90-day training period. Each service manager gets time to focus on training the new employees and help develop a training path. For example, it takes seven years of training to become a Toyota Gold Level Technician. Computer skills and equipment operation are part of that training. This means fewer service callbacks because equipment is fixed right the first time.”

Price pressure

Like any rental center, Hugg & Hall faces tremendous price pressure from its competitors. “Our customers are extremely price-conscious, and they have the data out there to find the very best price. There is much more quoting before ordering than even just five years ago. However, we find that once customers use our equipment and the related service that comes with it, they are much more likely to surpass the quoting process,” Hale says. “We shop rates, too, and we are very competitive.”

Part of meeting price pressure is to assure the equipment requested by the customer meets their needs. “We make sure we are supplying the right piece of equipment for the job. For example, a customer needs a boom or scissor lift for a 19-foot job doesn’t get a lift that can go 26 feet in the air. We ask many questions: for example, how high they must go, what are the loads, how wide are the doors? What are the weight limitations? We truly dial down what they need. Especially with the new generators, this is important. If a Tier 4 Final engine on a generator is running too light of a load, it will start wet stacking and over time, will harm the unit. We size the unit for the load, not just because we have that generator on hand and available for rent,” Hale says.